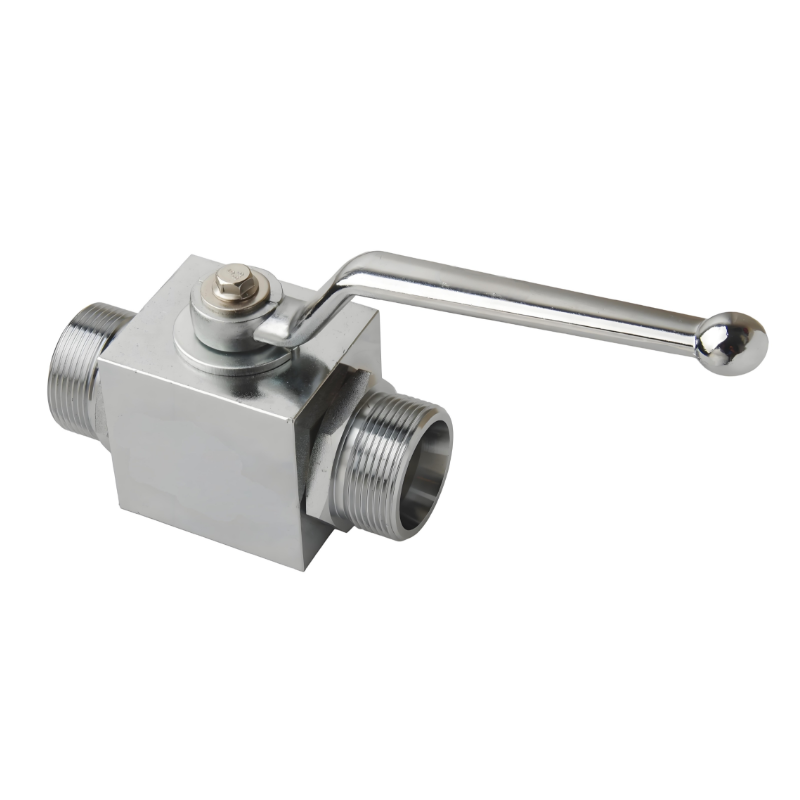

High Pressure Forged Ball Valve

Introduction

This article contains all the information you need to know about High Pressure forged ball Valves.

High Pressure Forged Ball Valve specification

High Pressure Forged Ball Valve actuator

Types of High Pressure Forged Ball Valve

Application of High Pressure Forged Ball Valve

Chapter 1 - High Pressure Forged Ball Valve Specification

High-pressure forged ball valves are constructed from high-strength materials to withstand extreme pressures and harsh operating conditions. Common materials include stainless steel (e.g., ASTM A182 F316, F304), carbon steel (e.g., ASTM A105), alloy steel (e.g., ASTM A182 F11, F22), duplex stainless steel (e.g., ASTM A182 F51), and other corrosion-resistant alloys.

Size

These valves come in a range of sizes to accommodate different piping systems and flow rates. Common sizes for high-pressure forged ball valves typically range from 1/2 inch to 12 inches or larger, depending on the application requirements.

Pressure Rating

High-pressure forged ball valves are designed to handle elevated pressure levels. They are available in various pressure classes, ranging from ANSI 600 to ANSI 2500 and higher. The pressure rating specifies the maximum pressure that the valve can withstand safely without compromising its integrity.

Temperature Range

High-pressure forged ball valves are designed to operate within specific temperature ranges dictated by the materials of construction and the fluid being handled. The temperature rating specifies the maximum and minimum temperatures at which the valve can safely operate without degradation or failure.

End Connections

High-pressure forged ball valves are available with various end connections to accommodate different piping configurations and installation requirements. The choice of end connection depends on factors such as pipe size, pressure rating, and the need for easy maintenance. Here are some common end connection options for high-pressure forged ball valves:

Threaded End Connections

Socket Weld End Connections

Butt Weld End Connections

Flanged End Connections

Hub End Connections

Chapter 2 - High Pressure Forged Ball Valve Actuator

High-pressure forged ball valves can be equipped with actuators to automate the valve operation, allowing for remote control and precise positioning in various industrial applications. Actuators provide the necessary force to open or close the valve, and they come in different types depending on the power source and control mechanism. Here are some common types of actuators used with high-pressure forged ball valves:

Pneumatic Actuators:

Pneumatic actuators use compressed air or gas to generate mechanical motion for operating the valve. They are widely used in industrial applications due to their reliability, fast response time, and suitability for high-pressure environments. Pneumatic actuators can be either single-acting (spring-return) or double-acting, depending on the direction of air flow and the desired valve action.

Electric Actuators:

Electric actuators use electric power to drive the valve operation, either through electric motors or electromechanical mechanisms. They offer precise control, variable speed, and compatibility with automation systems. Electric actuators are often used in applications where continuous modulation or remote control is required.

Hydraulic Actuators:

Hydraulic actuators utilize hydraulic fluid to generate linear or rotary motion for valve operation. They offer high force output and precise control, making them suitable for high-pressure and high-torque applications. Hydraulic actuators are commonly used in critical processes where precise valve positioning is essential.

Manual Override:

Some high-pressure forged ball valves equipped with actuators may include manual override devices to allow manual operation of the valve in case of power failure or emergency situations. Manual overrides can be handwheels, levers, or other mechanical mechanisms that provide a means for manual actuation when needed.

Spring-Return Actuators:

Actuators with spring-return mechanisms are designed to automatically return the valve to a pre-defined position (e.g., fully open or fully closed) in the event of a power loss or control signal failure. Spring-return actuators provide fail-safe operation and ensure valve closure in emergency situations.

Chapter 3 - High Pressure Forged Ball Valve Types

High-pressure forged ball valves are available in various types, each designed to meet specific application requirements and operating conditions. Here are some common types of high-pressure forged ball valves:

Two-Piece Design:

In a two-piece design, the valve body is constructed from two separate pieces that are bolted or threaded together. This design allows for easy maintenance and repair by providing access to internal components without removing the entire valve from the pipeline.

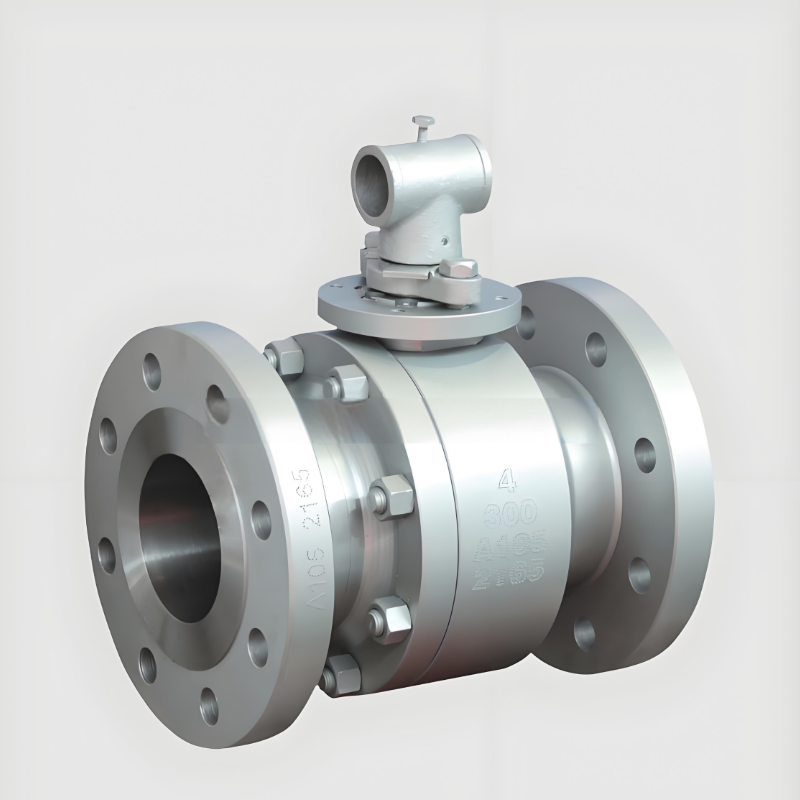

Three-Piece Design: Three-piece ball valves consist of three separate pieces: a central body section and two end caps. The valve body is assembled by bolting or threading the three pieces together. This design allows for easy disassembly and servicing of internal components, making it ideal for applications where frequent maintenance is required.

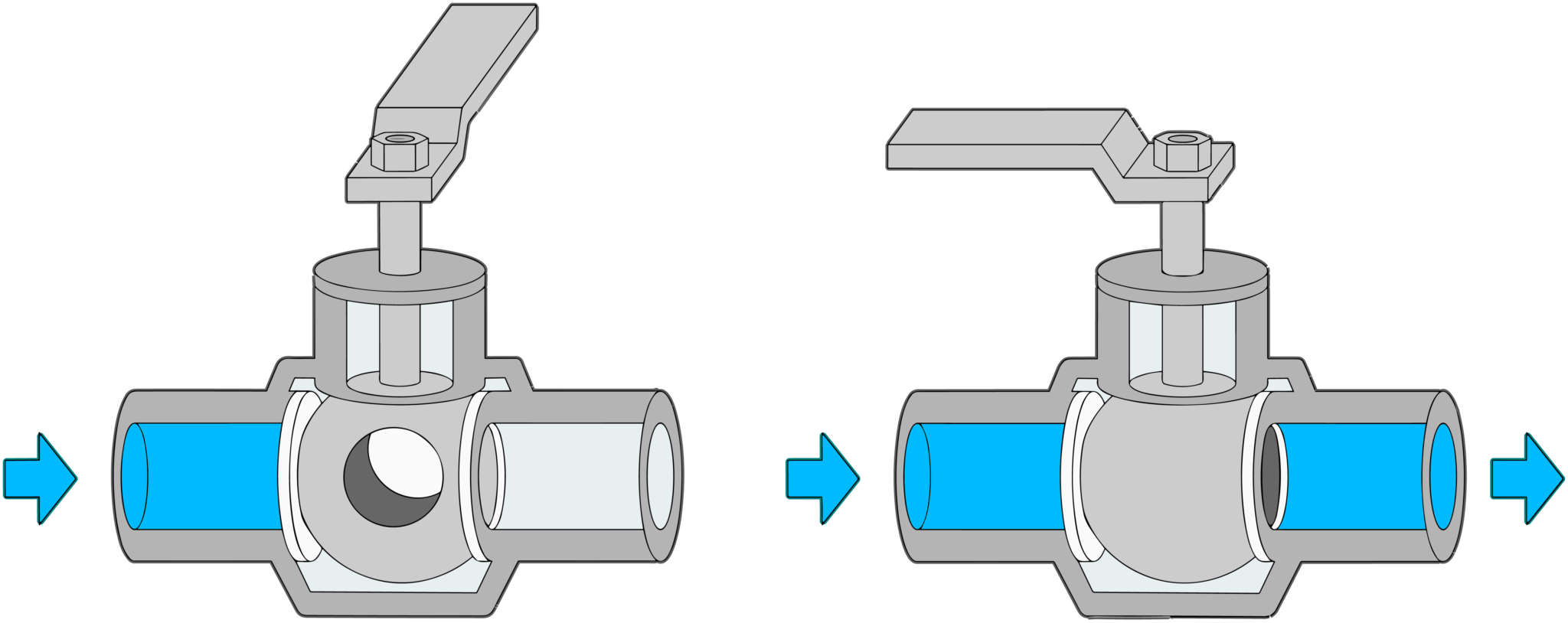

Floating Ball Valve:

In this type, the ball is not fixed to the stem but floats between the seat rings. When the pressure of the fluid increases, it pushes the ball against the seat, creating a seal. Floating ball valves are suitable for moderate to high-pressure applications.

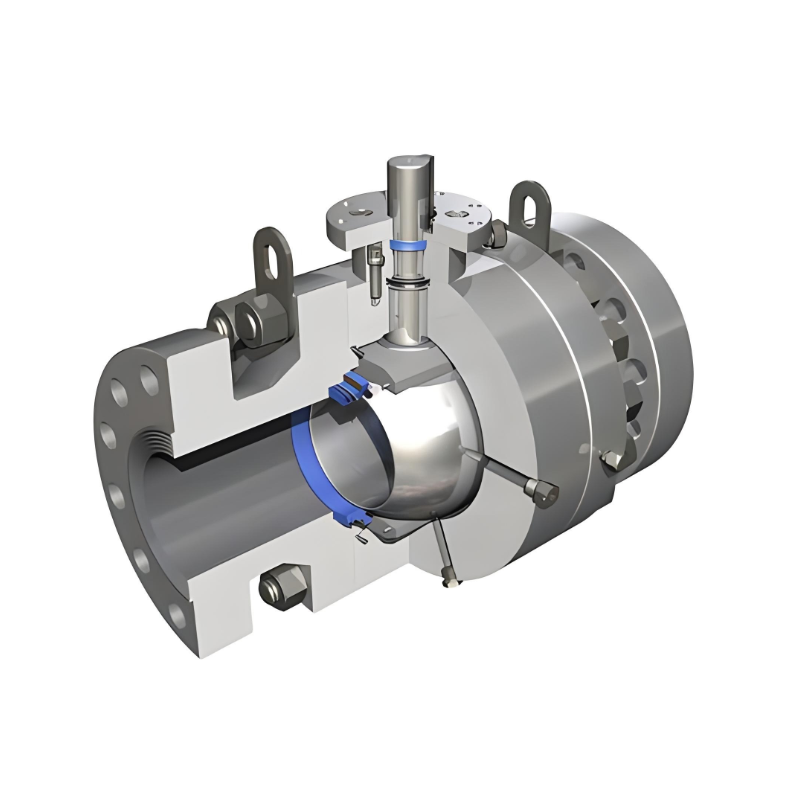

Trunnion Ball Valve:

Trunnion ball valves have additional mechanical anchoring of the ball at the top and bottom to withstand higher pressures and larger sizes. They are commonly used in pipelines with high-pressure or high-volume flow requirements.

These are just a few examples of the types of high-pressure forged ball valves available in the market. The choice of valve type depends on factors such as the application requirements, operating conditions, pressure and temperature ratings, and industry standards.

Chapter 4 - High Pressure Forged Ball Valve application

High-pressure forged ball valves find application in a wide range of industries and processes where reliable fluid control under high-pressure conditions is essential. Here are some common applications of high-pressure forged ball valves:

Oil and Gas Industry:

High-pressure forged ball valves are extensively used in upstream, midstream, and downstream operations of the oil and gas industry. They are employed in wellheads, pipelines, refineries, and petrochemical plants for controlling the flow of crude oil, natural gas, refined products, and various process fluids.

Chemical Processing:

High-pressure forged ball valves are suitable for handling corrosive and aggressive chemicals in chemical processing plants. They are used in reactors, storage tanks, and processing equipment to control the flow of acids, solvents, caustics, and other chemical substances.

Power Generation:

In power plants, high-pressure forged ball valves are employed in steam systems, feedwater systems, cooling water systems, and other critical applications. They help regulate the flow of steam, water, and other fluids in boiler systems, turbines, condensers, and auxiliary equipment.

Petrochemical Industry:

High-pressure forged ball valves play a crucial role in the petrochemical industry for controlling the flow of petrochemical products such as ethylene, propylene, benzene, and other hydrocarbons. They are used in processing units, storage facilities, and transportation systems.

Water and Wastewater Treatment:

In water and wastewater treatment plants, high-pressure forged ball valves are employed for controlling the flow of water, chemicals, and sludge in various treatment processes. They are used in filtration systems, disinfection units, pumping stations, and distribution networks.

Mining and Minerals Processing:

High-pressure forged ball valves are used in mining operations for controlling the flow of slurry, water, and chemicals in mineral processing plants. They are employed in grinding circuits, flotation cells, thickening tanks, and tailings disposal systems.

Marine and Offshore Applications:

High-pressure forged ball valves are utilized in marine and offshore environments for controlling the flow of seawater, fuel, and other fluids onboard ships, offshore platforms, and floating production units (FPUs). They are designed to withstand harsh marine conditions and comply with international maritime standards.

HVAC (Heating, Ventilation, and Air Conditioning):

High-pressure forged ball valves are used in HVAC systems for regulating the flow of water, refrigerants, and air in heating and cooling applications. They are employed in chillers, boilers, cooling towers, and air handling units.

Food and Beverage Industry:

In the food and beverage industry, high-pressure forged ball valves are employed for controlling the flow of process fluids such as water, steam, and food ingredients. They are used in production lines, storage tanks, and packaging equipment.

Aerospace and Defense:

High-pressure forged ball valves find application in aerospace and defense systems for controlling the flow of fluids in aircraft, spacecraft, missiles, and defense equipment. They are used in fuel systems, hydraulic systems, and propulsion systems.

These are just a few examples of the diverse applications of high-pressure forged ball valves across various industries. Their robust construction, reliable performance, and ability to withstand extreme conditions make them indispensable components in critical processes and systems.