Pound class Cast Steel Globe Valve

Introduction

This article contains all the information you need to know about Pound Class Cast Steel Globe Valve

Specification

Actuator

Types

Application

Chapter 1 - Specification

Here's a typical specification for a pound class (pressure class) cast steel globe valve:

Body Material

Cast steel, typically ASTM A216 WCB (carbon steel), ASTM A217 WC6 (chromium molybdenum steel), ASTM A217 WC9 (chromium molybdenum steel), or other suitable materials for corrosion resistance and strength.

Trim Material:

The trim materials are typically selected based on the fluid characteristics and service conditions. Common trim materials include stainless steel (ASTM A276 Type 316, ASTM A276 Type 304), carbon steel (ASTM A216 WCB), or other suitable alloys for erosion and corrosion resistance.

Seat Material:

Seats are usually made of materials such as stainless steel, stellite, or other hardened materials for excellent wear resistance and sealing performance.

Valve Size

Available in various sizes typically ranging from 1/2" to 24" (larger sizes may be available upon request).

Pressure Rating (Pound Class):

The pressure rating of the valve, denoted in pounds per square inch (psi), indicates the maximum pressure the valve can withstand. Common pound classes include:

Class 150: Suitable for low-pressure applications, typically up to 285 psi.

Class 300: Suitable for moderate-pressure applications, typically up to 740 psi.

Class 600: Suitable for high-pressure applications, typically up to 1480 psi.

Class 900, 1500, 2500: Suitable for very high-pressure applications, typically ranging from 2220 psi to 6415 psi.

Temperature Range

Suitable for operating temperatures ranging from -29°C to 593°C (-20°F to 1100°F) or higher, depending on material selection and pressure rating.

End Connections

Flanged ends, conforming to ASME B16.5 standards, with raised face (RF), flat face (FF), or ring joint face (RTJ) options available. Socket weld or butt weld ends may also be available upon request.

Design Standards:

The valve design should comply with international standards such as API 600, API 602, ASME B16.34, or equivalent for construction, design, and testing requirements.

Compliance:

The valve should comply with relevant industry standards and regulations such as ASME, ANSI, API, ASTM, MSS-SP, and others, depending on the application and location.

Chapter 2 - Pound Class Cast Steel Globe Valve Actuator

The selection of an actuator for a pound class cast steel globe valve depends on various factors including the valve size, pressure rating, operating conditions, and automation requirements of the system. Here are some common types of actuators used with pound class cast steel globe valves:

Manual Handwheel:

For smaller-sized valves or applications where manual operation is sufficient, a manual handwheel can be used. This simple actuator allows operators to manually open or close the valve by turning the handwheel.

Pneumatic Actuator:

Pneumatic actuators use compressed air to operate the valve. They are suitable for applications where quick and reliable valve operation is required. Pneumatic actuators can be spring-return or double-acting, depending on the application requirements.

Electric Actuator:

Electric actuators use an electric motor to drive the valve stem, allowing for precise control and automation of the valve operation. Electric actuators are suitable for applications where remote control and monitoring are required.

Hydraulic Actuator:

Hydraulic actuators use hydraulic pressure to operate the valve. They are suitable for applications requiring high force output and precise control. Hydraulic actuators are commonly used in high-pressure or high-torque applications.

Spring-Return Actuator:

Spring-return actuators use a spring mechanism to return the valve to a predetermined position (usually fully open or fully closed) in case of power failure or emergency shutdown. They are commonly used in safety-critical applications.

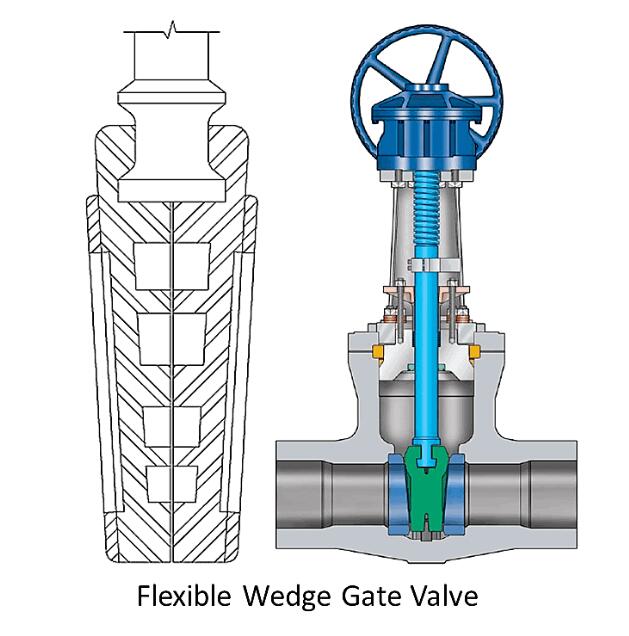

Chapter 3 - Pound Class Cast Steel Globe Valve Types

While there aren't distinct "types" of pound class cast steel globe valves in the same way as there are for other valve configurations like gate valves or ball valves, there are variations and features that differentiate them based on specific requirements and applications. Here are some common variations you might encounter:

Bolted Bonnet Globe Valve:

This is the most common type, featuring a bonnet bolted to the valve body, allowing for maintenance and repair.

Pressure Seal Globe Valve:

These valves are designed for high-pressure applications and feature a bonnet that is pressure-sealed to the valve body, eliminating the need for external bolting.

Bellows Seal Globe Valve:

Bellows seal globe valves feature a bellows-type seal between the valve stem and the bonnet, providing a leak-tight seal even in high-pressure and high-temperature applications.

Cryogenic Globe Valve:

These valves are designed to handle extremely low temperatures and are used in applications such as liquefied natural gas (LNG) handling or cryogenic storage facilities.

Extended Bonnet Globe Valve:

These have a bonnet that extends above the valve body, providing thermal insulation and protection for the valve stem. They are used in applications where the fluid temperature exceeds the temperature rating of standard valves.

Forged Steel Globe Valve:

Though not strictly a different "type," some globe valves are forged rather than cast. Forged steel globe valves offer high strength and reliability and are suitable for high-pressure applications.

Chapter 4 - Pound Class Cast Steel Globe Valve Application

Pound class cast steel globe valves find application in a wide range of industries and processes where reliable flow control, durability, and robust construction are essential. Here are some common applications:

Oil and Gas Industry:

Pound class cast steel globe valves are extensively used in upstream, midstream, and downstream operations within the oil and gas industry. They are employed in pipelines, wellheads, manifold systems, production facilities, refineries, and petrochemical plants for flow control of crude oil, natural gas, refined products, and various process fluids.

Power Generation:

Globe valves play a critical role in power plants for controlling the flow of steam, water, and other fluids in boiler feedwater systems, steam turbine bypass systems, cooling water systems, and auxiliary systems.

Chemical Processing:

Pound class cast steel globe valves are vital components in chemical processing plants for handling various fluids such as acids, alkalis, solvents, and hydrocarbons. They are commonly found in reactors, distillation columns, fractionation units, and storage tanks.

Water and Wastewater Treatment:

Globe valves are essential in water and wastewater treatment plants for controlling the flow of water, chemicals, and sludge. They are used in processes such as filtration, sedimentation, disinfection, chemical dosing, and wastewater conveyance.

Mining and Mineral Processing:

Pound class cast steel globe valves find application in mining and mineral processing operations for controlling the flow of slurries, chemicals, and process water in extraction, beneficiation, and dewatering processes.

Marine and Shipbuilding:

Globe valves are employed in marine and shipbuilding applications for controlling the flow of seawater, fuel, lubricants, and other fluids aboard ships, offshore platforms, and marine vessels.

HVAC Systems:

Pound class cast steel globe valves are widely used in heating, ventilation, and air conditioning (HVAC) systems for controlling the flow of hot water, chilled water, and refrigerants. They regulate the flow of fluids to maintain desired temperatures in buildings, industrial facilities, and commercial spaces.

Food and Beverage Industry:

Globe valves find application in the food and beverage industry for controlling the flow of ingredients, steam, and cleaning solutions. They are designed to meet sanitary standards and are used in brewing, dairy processing, food packaging, and other food-related processes.

Pharmaceutical Industry:

Pound class cast steel globe valves are utilized in pharmaceutical manufacturing facilities for controlling the flow of liquids, gases, and steam in various production processes. They are designed to meet stringent hygiene and purity requirements.

Fire Protection Systems:

Globe valves are incorporated into fire protection systems such as fire sprinkler systems and fire hydrants to control the flow of water or fire suppression agents in the event of a fire.