High Pressure Check Valve

Introduction

This article contains all the information you need to know about High Pressure Check Valve

Specification

Types

Application

Chapter 1 - Specification

Here's a typical specification for a cast steel swing check valve:

Body Material

Cast steel, typically ASTM A216 WCB (carbon steel), ASTM A217 WC6 (chromium molybdenum steel), ASTM A217 WC9 (chromium molybdenum steel), or other suitable materials for corrosion resistance and strength.

Trim Material:

The trim materials are typically selected based on the fluid characteristics and service conditions. Common trim materials include stainless steel (ASTM A276 Type 316, ASTM A276 Type 304), carbon steel (ASTM A216 WCB), or other suitable alloys for erosion and corrosion resistance.

Seat Material:

Seats are usually made of materials such as stainless steel, stellite, or other hardened materials for excellent wear resistance and sealing performance.

Valve Size

Available in various sizes typically ranging from 2" to 24" (larger sizes may be available upon request).

Bonnet Type:

Bolted bonnet design, allowing for easy maintenance and repair. Pressure seal bonnet design may also be available for high-pressure applications.

Pressure Rating

ANSI Class 150, 300, 600, 900, 1500, or 2500, indicating the maximum pressure the valve can withstand. The selection of pressure rating depends on the specific application requirements.

Temperature Range

Suitable for operating temperatures ranging from -29°C to 593°C (-20°F to 1100°F) or higher, depending on material selection and pressure rating.

End Connections

Flanged ends, conforming to ASME B16.5 standards, with raised face (RF), flat face (FF), or ring joint face (RTJ) options available. Socket weld or butt weld ends may also be available upon request.

Design Standards:

The valve design should comply with international standards such as API 6D, API 594, ASME B16.34, or equivalent for construction, design, and testing requirements.

Compliance:

The valve should comply with relevant industry standards and regulations such as ASME, ANSI, API, ASTM, MSS-SP, and others, depending on the application and location.

Chapter 2 - High Pressure Check Valve Types

High-pressure check valves are designed to withstand elevated pressures while providing reliable flow control. Here are some common types of high-pressure check valves:

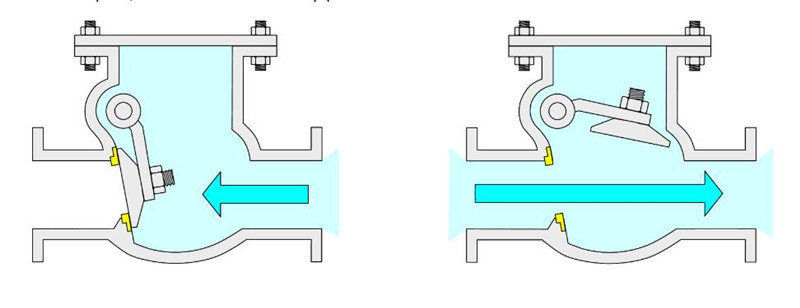

Swing Check Valve:

This is the most common type of check valve, consisting of a hinged disc that swings open to allow flow in one direction and closes to prevent backflow. Swing check valves are suitable for high-pressure applications and are available in various designs, including bolted bonnet, pressure seal bonnet, and welded bonnet.

Lift Check Valve:

Lift check valves feature a disc that moves vertically (upward or downward) to open or close the flow path. They are suitable for high-pressure applications where a larger disc area is required to withstand the pressure without excessive force on the disc.

Dual Plate Check Valve:

Also known as wafer check valves, dual plate check valves consist of two semicircular discs that are hinged in the center and swing open or closed in response to flow direction. They offer low pressure drop and fast response times, making them suitable for high-pressure applications where efficiency is critical.

Piston Check Valve:

Piston check valves use a piston-like disc that moves axially (back and forth) to open or close the flow path. They provide tight sealing and low pressure drop, making them suitable for high-pressure and high-temperature applications.

Stop Check Valve:

Stop check valves combine the features of a lift check valve and a globe valve. They feature a disc that lifts to allow flow in one direction and a stem that can be closed manually to stop flow in both directions. Stop check valves are suitable for applications where intermittent or manual control of flow is required in addition to check valve functionality.

Spring Check Valve:

Spring check valves feature a spring-loaded disc that opens to allow flow in one direction and closes under reverse flow pressure. They are suitable for high-pressure applications where quick response and positive sealing are required.

Chapter 3 - High Pressure Check Valve Application

High-pressure check valves are crucial components in various industries and systems where reliable flow control and backflow prevention are essential. Here are some common applications of high-pressure check valves:

Oil and Gas Industry:

High-pressure check valves are extensively used in upstream, midstream, and downstream operations within the oil and gas industry. They are installed in pipelines, wellheads, manifold systems, and production facilities to prevent backflow and maintain system integrity. They are particularly critical in high-pressure oil and gas wells and pipelines.

Petrochemical Plants:

These valves play a vital role in petrochemical plants for controlling the flow of process fluids, including chemicals, solvents, and hydrocarbons. They are installed in reactors, distillation columns, fractionation units, and storage tanks to prevent reverse flow and ensure safe and efficient operation.

Power Generation:

High-pressure check valves are used in power plants for controlling the flow of steam, condensate, and cooling water. They are installed in boiler feedwater systems, steam turbines, condensers, and cooling towers to prevent backflow and maintain system efficiency and reliability.

Chemical Processing:

High-pressure check valves find application in chemical processing plants for controlling the flow of corrosive chemicals, acids, and caustic solutions. They are used in pipelines, reactors, and storage tanks to prevent backflow and protect equipment from damage.

Water and Wastewater Treatment:

These valves are critical components in water and wastewater treatment plants for preventing backflow and protecting equipment such as pumps, filters, and disinfection systems. They are installed in pipelines, lift stations, and treatment facilities to maintain the flow of water and sewage in the intended direction.

Mining and Minerals:

High-pressure check valves are utilized in mining and mineral processing operations for controlling the flow of slurries, mine tailings, and process fluids. They are installed in pipelines, pumps, and processing equipment to prevent backflow and ensure efficient material handling.

Fire Protection Systems:

Swing check valves are incorporated into fire protection systems such as fire sprinkler systems and fire hydrants to prevent backflow of water or fire suppression agents. They ensure that water or foam is delivered to the fire source without interruption.

Marine and Offshore Applications:

High-pressure check valves are used in marine and offshore systems for controlling the flow of seawater, ballast water, and hydraulic fluids. They are installed in piping systems aboard ships, offshore platforms, and marine vessels to prevent backflow and maintain system reliability.

Chemical Processing:

Swing check valves find application in chemical processing plants for controlling the flow of corrosive chemicals, acids, and caustic solutions. They are used in pipelines, reactors, and storage tanks to prevent backflow and protect equipment from damage.

Food and Beverage Industry:

Swing check valves are employed in the food and beverage industry for preventing backflow and maintaining sanitary conditions in processing plants. They are installed in pipelines, mixing vessels, and filling machines to ensure the flow of food products in the intended direction.