High pressure forged steel gate valve

Introduction

This article contains all the information you need to know about High Pressure Forged Steel Gate Valve

Read further and learn more about:

Specification

Actuator

Types

Application

Chapter 1 - Material

Here's a typical specification for a high-pressure forged steel gate valve:

Material

The body, bonnet, and gate of the valve are made of forged steel (usually ASTM A105 for carbon steel or ASTM A182 F316 for stainless steel), providing strength, durability, and resistance to high-pressure and high-temperature conditions.

Size

High-pressure forged steel gate valves are available in a range of sizes, typically from 1/2 inches to 2 inches or larger, to accommodate various piping systems and flow requirements.

Pressure Rating

The valve is designed to withstand high-pressure applications, typically ranging from Class 1500 to Class 4500, indicating its ability to handle different levels of pressure. Higher pressure classes are suitable for more demanding applications.

Temperature Range

The valve is designed to operate within a specified temperature range, determined by the material selection and construction. Special materials or coatings may be required for extreme temperature applications.

End Connections

High-pressure forged steel gate valves typically have socket weld or threaded end connections to ANSI B16.11 standards. Socket weld valves are suitable for smaller sizes, while threaded valves are used for larger sizes. The choice of end connections depends on the requirements of the piping system and the installation conditions.

Pressure Testing:

The valve undergoes pressure testing in accordance with API 598 or ASME B16.34 standards to ensure its integrity and leak-tightness under high-pressure conditions.

Sealing Mechanism:

The gate valve features a metal-to-metal or resilient seat design to provide a tight shut-off when the valve is fully closed. The sealing mechanism ensures leak-free performance and prevents fluid bypass.

Chapter 2 - High Pressure Forged Steel Gate Valve Actuator

High-pressure forged steel gate valves typically utilize manual operation due to their robust design and the nature of their applications. However, in some cases where remote or automated operation is required, various types of actuators can be employed. Here are some common actuators used with high-pressure forged steel gate valves:

Manual Actuator:

In critical applications or where power sources may be unreliable, a manual override mechanism can be added to the actuator. This allows the valve to be manually operated in the event of a power failure or loss of pneumatic/hydraulic pressure. Manual override options may include handwheels, levers, or crank handles.

Electric Actuators:

Electric actuators use an electric motor to generate mechanical motion for opening and closing the valve. They are suitable for applications where remote operation, precise control, and automation are required. Electric actuators can be controlled remotely and integrated into control systems for advanced functionality such as position feedback, torque sensing, and remote monitoring. They are often used in critical applications where continuous monitoring and control are necessary.

Hydraulic Actuators:

Hydraulic actuators use hydraulic fluid to generate mechanical motion for operating the valve. They offer high force output and precise control, making them suitable for applications where a large amount of force is required to operate the valve or where precise positioning is critical. Hydraulic actuators are commonly used in heavy-duty industrial applications where high-pressure and high-temperature conditions are present.

Pneumatic Actuator:

Pneumatic actuators use compressed air to generate mechanical motion for operating the valve. They are commonly used in industrial applications where rapid valve operation and precise control are required. Pneumatic actuators offer fast response times, high reliability, and are suitable for both on-off and throttling applications. They are often preferred in hazardous environments where electric actuators may pose a risk.

Chapter 3 - High Pressure Forged Steel Gate Valve Types

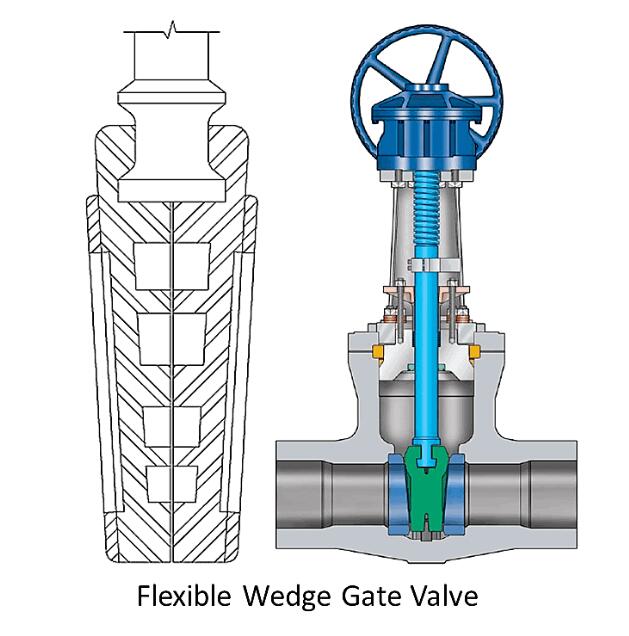

High-pressure forged steel gate valves are designed to withstand demanding conditions and are available in various types to suit different applications. Here are some common types of high-pressure forged steel gate valves:

Bolted Bonnet Gate Valve:

Bolted bonnet gate valves feature a bonnet that is bolted to the valve body. This design allows for easy maintenance and repair by removing the bonnet to access internal components such as the gate, stem, and seats. Bolted bonnet gate valves are commonly used in applications where periodic inspection and maintenance are required.

Pressure Seal Gate Valve:

Pressure seal gate valves are specifically designed for high-pressure and high-temperature applications. They feature a unique pressure seal bonnet design that provides a tight seal against the body at elevated pressures. Pressure seal gate valves are commonly used in power generation, oil and gas, and petrochemical industries.

Welded Bonnet Gate Valve:

Welded bonnet gate valves have a bonnet that is welded to the valve body, providing a hermetic seal and enhanced structural integrity. This design is suitable for applications with severe operating conditions and high pressures. Welded bonnet gate valves are commonly used in critical service applications where leakage prevention is paramount.

Extended Bonnet Gate Valve:

Extended bonnet gate valves feature an elongated bonnet that provides insulation and protection for the stem and packing gland in high-temperature applications. These valves are used in processes where the fluid temperature exceeds the temperature rating of standard valves. Extended bonnet gate valves are commonly used in petrochemical, chemical processing, and power generation industries.

Cryogenic Gate Valve:

Cryogenic gate valves are designed to handle extremely low temperatures, typically below -50°C (-58°F). These valves are used in cryogenic applications such as liquefied natural gas (LNG) processing, industrial gases, and aerospace applications. Cryogenic gate valves are constructed with materials and seals that can withstand the challenges of low temperatures without compromising performance.

API 602 Gate Valve:

API 602 gate valves, also known as forged steel gate valves, are designed and manufactured according to the requirements of API Standard 602. These valves are widely used in oil and gas production, refining, and pipeline transmission systems. API 602 gate valves are available in various materials, pressure classes, and end connections to meet industry requirements.

Chapter 4 - High Pressure Forged Steel Gate Valve Application

High-pressure forged steel gate valves are utilized in a wide range of applications across various industries where reliable, bi-directional isolation and tight shut-off are required under demanding operating conditions. Here are some common applications of high-pressure forged steel gate valves:

Oil and Gas Industry:

High-pressure forged steel gate valves are extensively used in the oil and gas industry for upstream, midstream, and downstream applications. They are employed in wellheads, production manifolds, pipelines, refineries, and petrochemical plants to control the flow of crude oil, natural gas, and other hydrocarbons.

Refining and Petrochemical Plants:

Gate valves are crucial components in refining and petrochemical plants for controlling the flow of various process fluids such as crude oil, refined products, chemicals, and solvents. They are used in distillation columns, reactors, separators, and storage tanks to regulate process flow and isolate equipment.

Power Generation:

High-pressure forged steel gate valves play a vital role in power generation facilities for controlling the flow of steam, water, and other fluids in boiler feedwater systems, steam turbines, condensate lines, and cooling water circuits. They ensure reliable operation and safety in power plants.

Pipeline Transmission:

Gate valves are installed along pipeline networks for oil, gas, water, and other fluids to provide sectional isolation, facilitate maintenance activities, and control the flow during normal operation and emergency shutdowns. They are essential for the transportation of fluids over long distances.

Chemical Processing:

High-pressure forged steel gate valves are used in chemical processing plants for regulating the flow of corrosive chemicals, acids, solvents, and process fluids. They are employed in reactors, distillation columns, mixing vessels, and storage tanks to ensure safe and efficient operation of chemical processes.

Mining and Minerals Processing:

Gate valves find application in mining operations for controlling the flow of slurries, process water, and chemicals in ore processing plants, tailings ponds, and mine dewatering systems. They are essential for the extraction and processing of minerals and metals.

Marine and Offshore Applications:

Gate valves are used in marine and offshore environments aboard ships, vessels, and offshore platforms. They control the flow of seawater, ballast water, fuel, and other fluids in propulsion systems, cargo handling systems, and emergency shutdown systems.

Water and Wastewater Treatment:

High-pressure forged steel gate valves are utilized in water and wastewater treatment facilities for regulating the flow of raw water, treated water, and chemicals. They are used in processes such as filtration, sedimentation, disinfection, and sludge handling to control flow rates and manage process conditions.