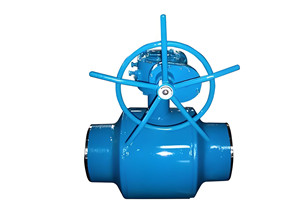

All-welded Ball Valve

Introduction

This article contains all the information you need to know about All-welded Ball Valve

Specification

Actuator

Types

Application

Chapter 1 - All-welded Ball Valve Specification

Here's a basic specification outline for an all-welded ball valve:

Material:

Body: Typically made of stainless steel, carbon steel, or other corrosion-resistant alloys.

Ball: Same material as the body.

Seats and Seals: Materials suitable for the intended application and compatible with the fluid being handled.

Stem: Usually made of stainless steel or other corrosion-resistant material.

Pressure Rating

State the maximum pressure the valve is designed to withstand, usually given in pounds per square inch (psi) or bar.

End Connections

Specify the type of end connections (e.g., butt weld, socket weld) and the standard (e.g., ASME B16.25) to which they conform.

Design Standards:

Specify the standards the valve is designed and manufactured to meet, such as API, ASME, ANSI, ISO, etc.

Chapter 2 - All-welded Ball Valve Actuator

When specifying an actuator for an all-welded ball valve, consider the following details:

Type of Actuator:

Pneumatic: Uses compressed air to operate the valve.

Electric: Utilizes electric power for valve operation.

Hydraulic: Operates using hydraulic pressure.

Manual: Operated manually without any external power source.

Actuator Size:

Select an actuator size appropriate for the valve size and the torque or force required to operate the valve.

Operating Voltage (for electric actuators):

Specify the voltage requirement for electric actuators (e.g., 110V AC, 24V DC).

Actuator Control Type:

For electric actuators, specify if it's on-off, modulating, or with position feedback.

For pneumatic actuators, specify if it's single-acting (spring return) or double-acting.

Chapter 3 - All-welded Ball Valve Types

All-welded ball valves are commonly used in industries where high pressure, high temperature, and corrosive conditions are prevalent. They offer reliability, durability, and minimal maintenance due to their welded construction. Here are some common types of all-welded ball valves:

Floating Ball Valve:

In a floating ball valve, the ball is not fixed to the stem but is free to move slightly within the valve body.

Sealing is achieved by pressure exerted on the ball, which forces it against the downstream seat.

This type is suitable for moderate pressure and temperature applications.

Trunnion Mounted Ball Valve:

In a trunnion mounted ball valve, the ball is supported by trunnions, which are anchored to the valve body.

This design is ideal for high-pressure applications as it provides additional support to the ball, reducing the operating torque.

It offers better sealing performance and is suitable for larger valve sizes and higher pressure ratings.

Fully Welded Trunnion Ball Valve:

This type of ball valve has a fully welded body construction without any bolted connections, providing enhanced strength and integrity.

It is suitable for buried or underground applications, as well as in pipelines carrying hazardous fluids.

Offers reduced potential for leakage and improved safety.

High-Temperature Ball Valve:

High-temperature ball valves are designed to withstand elevated temperatures, typically above 400°C (752°F).

They are used in applications such as steam, thermal oil, and high-temperature gases.

Materials with high temperature resistance and thermal stability are employed in their construction.

Each type of all-welded ball valve has its own advantages and is selected based on the specific requirements of the application, including pressure, temperature, fluid characteristics, and environmental conditions.

Chapter 4 - All-welded Ball Valve application

All-welded ball valves find application in various industries and processes where their robust construction, reliability, and resistance to high pressure and corrosive environments are advantageous. Here are some common applications:

Oil and Gas Industry

All-welded ball valves are used in upstream, midstream, and downstream operations within the oil and gas industry.

Applications include isolation and control of crude oil, natural gas, refined products, and various fluids in pipelines, refineries, production facilities, and storage terminals.

They are suitable for high-pressure, high-temperature, and corrosive environments commonly encountered in oil and gas operations.

Chemical Processing

All-welded ball valves are utilized in chemical plants for handling corrosive chemicals, acids, bases, and solvents.

They provide reliable shut-off and control in chemical reactors, storage tanks, and distribution systems where resistance to chemical corrosion is essential.

Power Generation

In power plants, all-welded ball valves are employed in steam systems, cooling water circuits, and fuel handling systems.

They are used for isolation and control in boiler feedwater, steam lines, turbine bypass systems, and condensate return lines.

Water and Wastewater Treatment:

All-welded ball valves are used in municipal and industrial water treatment facilities for controlling the flow of water, chemicals, and wastewater.

Applications include water distribution systems, sewage treatment plants, desalination plants, and water intake/outfall systems.

Mining and Minerals Processing:

All-welded ball valves are utilized in mining operations for handling abrasive slurries, acids, and other process fluids.

They provide reliable shut-off and control in processes such as ore crushing, grinding, flotation, and tailings disposal.

Marine and Offshore Applications:

All-welded ball valves are used in marine and offshore environments for applications such as seawater intake/outfall, ballast systems, and offshore platform piping.

They offer corrosion resistance and reliability in harsh marine environments.

These are just a few examples of the diverse range of applications where all-welded ball valves are used. Their versatility, durability, and ability to withstand demanding operating conditions make them a preferred choice in many industries.