Hard Metal Seal Butterfly Valve

Introduction

This article contains all the information you need to know about Hard Metal Seal Butterfly Valve

Read further and learn more about:

Specification

Actuators

Types

Application

Chapter 1 - Specification

Here's a typical specification for a Hard Metal Seal Butterfly Valve

Body Material

Cast steel, typically ASTM A216 WCB (carbon steel), ASTM A217 WC6 (chromium molybdenum steel), ASTM A217 WC9 (chromium molybdenum steel), or other suitable materials for corrosion resistance and strength.

Trim Material:

The trim materials are typically selected based on the fluid characteristics and service conditions. Common trim materials include stainless steel (ASTM A276 Type 316, ASTM A276 Type 304), carbon steel (ASTM A216 WCB), or other suitable alloys for erosion and corrosion resistance.

Seat Material:

Seats are usually made of materials such as stainless steel, stellite, or other hardened materials for excellent wear resistance and sealing performance.

Valve Size

Available in various sizes typically ranging from 2" to 24" (larger sizes may be available upon request).

Bonnet Type:

Bolted bonnet design, allowing for easy maintenance and repair. Pressure seal bonnet design may also be available for high-pressure applications.

Pressure Rating

ANSI Class 150, 300, 600, 900, 1500, or 2500, indicating the maximum pressure the valve can withstand. The selection of pressure rating depends on the specific application requirements.

Temperature Range

Suitable for operating temperatures ranging from -29°C to 593°C (-20°F to 1100°F) or higher, depending on material selection and pressure rating.

End Connections

Flanged ends, conforming to ASME B16.5 standards, with raised face (RF), flat face (FF), or ring joint face (RTJ) options available. Socket weld or butt weld ends may also be available upon request.

Design Standards:

The valve design should comply with international standards such as API 6D, API 594, ASME B16.34, or equivalent for construction, design, and testing requirements.

Compliance:

The valve should comply with relevant industry standards and regulations such as ASME, ANSI, API, ASTM, MSS-SP, and others, depending on the application and location.

Chapter 2 - Hard Metal Seal Butterfly Valve Actuators

For hard metal seal butterfly valves, actuators play a crucial role in controlling the valve's movement and flow regulation. Here are some common types of actuators used with hard metal seal butterfly valves:

Electric Actuators:

Electric actuators utilize an electric motor to operate the valve. They offer precise control over valve positioning and can be easily integrated into control systems. Electric actuators are suitable for applications where remote operation, automation, and precise positioning are required. They are often used in industries such as water treatment, HVAC, and process automation.

Pneumatic Actuators:

Pneumatic actuators use compressed air to operate the valve. They provide fast and reliable valve actuation, making them suitable for applications where quick response times are necessary. Pneumatic actuators are commonly used in industries such as petrochemicals, oil and gas, and power generation, where robust and efficient valve control is essential.

Hydraulic Actuators:

Hydraulic actuators use hydraulic fluid to operate the valve. They offer high force output and precise control over valve movement, making them suitable for high-pressure and high-torque applications. Hydraulic actuators are commonly used in industries such as marine, offshore, and heavy machinery, where reliable and powerful valve actuation is required.

Manual Actuators:

Manual actuators are operated manually by hand or using a lever. They are simple and cost-effective solutions for applications where automation is not required, or where valves need to be operated manually for maintenance or emergency purposes. Manual actuators are commonly used in small-scale systems, laboratories, and test rigs.

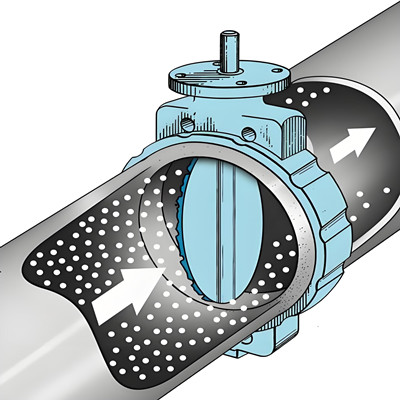

Chapter 3 - Hard Metal Seal Butterfly Valve Types

Hard metal seal butterfly valves are designed to withstand high temperatures, pressures, and corrosive environments. Here are some common types of hard metal seal butterfly valves:

Metal Seated Butterfly Valve:

Metal seated butterfly valves feature metal-to-metal contact between the disc and the seat, providing tight shut-off and resistance to abrasion and erosion. They are suitable for high-temperature and abrasive applications, such as in power plants, chemical processing, and mining.

Triple Offset Butterfly Valve:

Triple offset butterfly valves have a conical metal seat with three offsets from the centerline of the valve shaft. This design minimizes friction and wear between the disc and seat, resulting in tight shut-off and reduced torque during operation. Triple offset butterfly valves are used in high-pressure and high-temperature applications, such as in oil and gas, refining, and petrochemical industries.

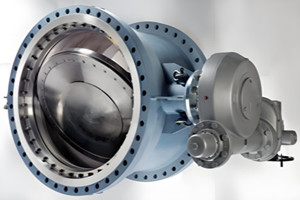

High-Performance Butterfly Valve:

High-performance butterfly valves are designed for high-pressure and high-temperature applications where tight shut-off and reliable performance are essential. They feature metal seats and a robust construction to withstand demanding operating conditions. High-performance butterfly valves are commonly used in industries such as power generation, oil and gas, and chemical processing.

Bi-Directional Butterfly Valve:

Bi-directional butterfly valves are designed to operate in both flow directions, providing flexibility in system design and installation. They feature metal seats and a symmetrical disc design to ensure tight shut-off in both flow directions. Bi-directional butterfly valves are suitable for applications where flow reversal may occur, such as in water treatment, HVAC, and marine systems.

Cryogenic Butterfly Valve:

Cryogenic butterfly valves are designed for low-temperature applications, such as in liquefied natural gas (LNG) processing, cryogenic storage, and aerospace industries. They feature metal seats and special materials that can withstand extremely low temperatures while maintaining tight shut-off and reliable performance.

Fire-Safe Butterfly Valve:

Fire-safe butterfly valves are designed to withstand high temperatures and maintain tight shut-off in the event of a fire. They feature metal seats and seals that can withstand fire exposure without compromising integrity. Fire-safe butterfly valves are used in fire protection systems, oil and gas installations, and chemical processing plants.

API 609 Butterfly Valve:

API 609 butterfly valves comply with the American Petroleum Institute (API) standard 609 for butterfly valves. They are designed for high-performance applications in oil and gas, refining, and petrochemical industries. API 609 butterfly valves may feature metal seats and seals to ensure reliable performance in demanding environments.

Chapter 4 - Hard Metal Seal Butterfly Valve Application

Hard metal seal butterfly valves are widely used in various industries and applications where reliable shut-off, high temperatures, high pressures, and corrosive fluids are present. Here are some common applications of hard metal seal butterfly valves:

Oil and Gas Industry:

Hard metal seal butterfly valves are used in upstream, midstream, and downstream operations within the oil and gas industry. They are installed in pipelines, wellheads, manifold systems, and processing facilities to control the flow of crude oil, natural gas, and refined products. These valves are suitable for high-pressure and high-temperature applications, as well as corrosive environments found in offshore platforms, refineries, and petrochemical plants.

Chemical Processing:

Hard metal seal butterfly valves find application in chemical processing plants for handling corrosive chemicals, acids, and solvents. They are used in reactors, distillation columns, storage tanks, and mixing vessels to control the flow of process fluids and maintain system integrity. These valves offer tight shut-off and resistance to chemical corrosion, making them suitable for aggressive chemical environments.

Power Generation:

Hard metal seal butterfly valves are utilized in power plants for controlling the flow of steam, water, and other fluids in boiler feedwater systems, steam turbines, condensers, and cooling towers. They are designed to withstand high temperatures, pressures, and steam conditions commonly encountered in power generation facilities. These valves provide reliable shut-off and flow control in critical steam and water applications.

Mining and Minerals:

Hard metal seal butterfly valves are used in mining and mineral processing operations for controlling the flow of slurries, mine tailings, and process fluids. They are installed in pipelines, pumps, and processing equipment to handle abrasive and corrosive materials found in mining operations. These valves offer tight shut-off and resistance to abrasion and erosion, making them suitable for harsh mining environments.

Water and Wastewater Treatment:

Hard metal seal butterfly valves find application in water and wastewater treatment plants for controlling the flow of water, chemicals, and sludge. They are used in pipelines, treatment tanks, and filtration systems to regulate fluid flow and maintain process efficiency. These valves offer resistance to corrosion and chemical attack, ensuring reliable performance in water treatment applications.

Marine and Offshore:

Hard metal seal butterfly valves are employed in marine and offshore applications for controlling the flow of seawater, ballast water, and hydraulic fluids. They are installed in piping systems aboard ships, offshore platforms, and marine vessels to regulate fluid flow and maintain system reliability in challenging marine environments. These valves offer resistance to corrosion, erosion, and fouling, making them suitable for marine applications.