Forged Steel Globe Valve

Introduction

This article contains all the information you need to know about Forged Steel Globe Valve

Specification

Actuator

Types

Application

Chapter 1 - Specification

Forged steel globe valves are commonly used in high-pressure and high-temperature applications. Here's a typical specification for a forged steel globe valve:

Body Material

Forged steel (ASTM A105, ASTM A182 F316, ASTM A182 F304, etc.) for excellent strength and corrosion resistance.

Trim Material:

Typically, trim materials include stainless steel (ASTM A182 F316, ASTM A182 F304, etc.) or other alloys for resistance to corrosion and wear.

Seat Material:

Hard-faced (Stellite, etc.) or soft-seated (PTFE, etc.) depending on the service conditions.

Valve Size

Usually ranging from 1/4" to 2" for forged steel globe valves.

Pressure Rating

ANSI Class 800, 1500, 2500, or higher depending on the application requirements.

Temperature Range

Suitable for operating temperatures ranging from -29°C to 593°C (-20°F to 1100°F) or higher, depending on material selection.

End Connections

NPT, SW, RF, RTJ, or BW, as per standards such as ASME B16.11, ASME B16.5, ASME B16.25, etc.

Chapter 2 - Forged Steel Globe Valve Actuator

Forged steel globe valves can be equipped with various types of actuators to automate their operation. The choice of actuator depends on factors such as the valve size, pressure rating, application requirements, and control system preferences. Here are some common types of actuators used with forged steel globe valves:

Manual Actuator:

Some actuators, especially electric and pneumatic ones, may come with a manual override feature. This allows manual operation of the valve in case of power or air supply failure.

Electric Actuators:

These actuators use an electric motor to drive the valve stem, opening or closing the valve upon receiving electrical signals. Electric actuators are often preferred for precise control and automation in industrial processes. They can be further classified into:

Rotary Electric Actuators: Convert rotary motion into linear motion to operate the valve stem.

Linear Electric Actuators: Directly convert electrical energy into linear motion to drive the valve stem.

Hydraulic Actuators:

Hydraulic actuators utilize hydraulic pressure to operate the valve. They are suitable for applications requiring high force output and precise control.

Pneumatic Actuator:

Pneumatic actuators use compressed air to operate the valve. They are commonly used in applications where electricity is not readily available or in hazardous environments where sparks need to be avoided.

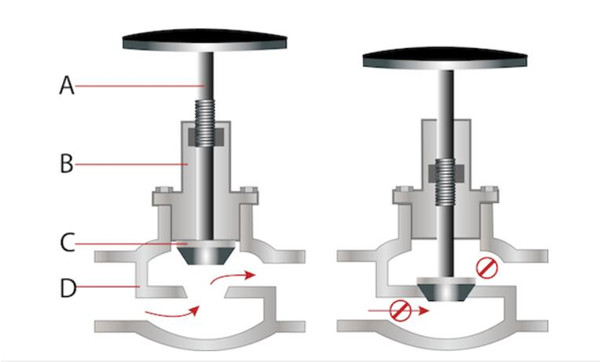

Chapter 3 - Forged Steel Globe Valve Types

Forged steel globe valves come in various types, each designed for specific applications and operating conditions. Here are some common types of forged steel globe valves:

Bolted Bonnet Globe Valve:

This is the most common type of globe valve. It features a bonnet that is bolted to the valve body, providing a robust seal and allowing for maintenance and repair of internal components.

Welded Bonnet Globe Valve:

In this type, the bonnet is welded to the valve body, creating a hermetic seal. Welded bonnet globe valves are suitable for high-pressure and high-temperature applications where leak-tightness is critical.

Pressure Seal Globe Valve:

Pressure seal globe valves are designed for high-pressure applications. They feature a bonnet that is pressure-sealed to the valve body, eliminating the need for external bolting. These valves are commonly used in power plants, petrochemical plants, and other industrial settings.

Cryogenic Globe Valve

Cryogenic globe valves are designed to handle extremely low temperatures, typically below -50°C (-58°F). They feature extended bonnets and special materials to prevent valve components from becoming brittle at cryogenic temperatures.

Forged Steel Bellows Seal Globe Valve

Similar to the bellows seal globe valve, this type features a forged steel construction for enhanced strength and durability in high-pressure and high-temperature applications.

Chapter 4 - Forged Steel Globe Valve Application

Forged steel globe valves find application in various industries and processes where reliable flow control is essential. Here are some common applications of forged steel globe valves:

Power Generation:

Globe valves are used in power plants for controlling the flow of steam, water, and other fluids in boiler feedwater systems, steam turbine bypass systems, cooling water systems, and other auxiliary systems.

Oil and Gas Industry:

Globe valves are employed in upstream, midstream, and downstream operations within the oil and gas industry. They are used for flow control in pipelines, wellheads, manifold systems, production facilities, and refineries.

Petrochemical and Chemical Processing:

Globe valves are utilized in petrochemical and chemical processing plants for handling various fluids such as acids, alkalis, solvents, and hydrocarbons. They are commonly found in reactors, distillation columns, fractionation units, and storage tanks.

Water and Wastewater Treatment:

Globe valves play a crucial role in water and wastewater treatment plants for controlling the flow of water, chemicals, and sludge. They are used in processes such as filtration, sedimentation, disinfection, and chemical dosing.

Marine and Shipbuilding:

Globe valves are utilized in marine and shipbuilding applications for controlling the flow of seawater, fuel, lubricants, and other fluids aboard ships and offshore platforms.

Food and Beverage Industry:

Globe valves are employed in food and beverage processing plants for controlling the flow of ingredients, steam, and cleaning solutions. They are designed to meet sanitary standards and are used in applications such as brewing, dairy processing, and food packaging.

Mining and Mineral Processing:

Globe valves are utilized in mining and mineral processing operations for controlling the flow of slurries, chemicals, and process water in extraction, beneficiation, and dewatering processes.

Fire Protection Systems:

Globe valves are incorporated into fire protection systems such as fire sprinkler systems and fire hydrants to control the flow of water or fire suppression agents in the event of a fire.

HVAC Systems:

Globe valves are used in heating, ventilation, and air conditioning (HVAC) systems for controlling the flow of hot water, chilled water, and refrigerants. They regulate the flow of fluids to maintain desired temperatures in buildings, industrial facilities, and commercial spaces.