Stainless steel gate valve

Introduction

This article contains all the information you need to know about Stainless Steel Gate Valve

Read further and learn more about:

Specification

Actuator

Types

Application

Chapter 1 - Specification

The specifications for a stainless steel gate valve can vary depending on factors such as its intended application, pressure rating, size, and specific industry standards.

Material

Stainless steel (often grade 304 or 316) for the body, gate, stem, and other components.

Size

Gate valves are available in a range of sizes, typically from 1/2 inch to 48 inches or larger.

Pressure Rating

Gate valves are designed to withstand different levels of pressure. Common pressure ratings include Class 150, 300, 600, 900, 1500, and 2500.

Temperature Range

The valve's temperature range should be suitable for the intended application.

End Connections

Gate valves can have various end connections such as flanged, threaded, socket weld, or butt weld.

Chapter 2 - Stainless Steel Gate Valve actuator

The actuator for a stainless steel gate valve can vary depending on factors such as the valve size, pressure rating, intended application, and automation requirements. Here are some common types of actuators used with stainless steel gate valves:

Manual Actuator:

This is the simplest form of actuator, usually a handwheel or lever, which allows manual operation of the gate valve. Manual actuators are suitable for applications where infrequent operation is required or where automation is not feasible.

Electric Actuators:

Electric actuators use an electric motor to open and close the gate valve. They can be controlled remotely and integrated into automated systems, offering precise control over valve positioning. Electric actuators are suitable for applications where remote operation and precise control are necessary.

Hydraulic Actuators:

Hydraulic actuators use hydraulic fluid to operate the gate valve. They offer high force output and are suitable for applications where a large amount of force is required to operate the valve. Hydraulic actuators are commonly used in heavy-duty industrial applications.

Pneumatic Actuator:

Pneumatic actuators use compressed air to operate the gate valve. They are often used in industrial applications where electricity is not readily available or where explosion-proof operation is required. Pneumatic actuators are known for their fast response times and high reliability.

Chapter 3 - Stainless Steel Gate Valve Types

Stainless steel gate valves come in various types, each designed for specific applications and operational requirements. Here are some common types:

Rising Stem Gate Valve:

In this type of gate valve, the stem rises and lowers along with the gate to indicate the valve position. It's often used in applications where visual indication of the valve position is required.

Non-Rising Stem Gate Valve:

In contrast to the rising stem design, the stem of a non-rising stem gate valve remains stationary while the gate moves up and down to open and close the valve. This design is often used in applications where space is limited.

Solid Wedge Gate Valve:

Solid wedge gate valves have a single, solid gate that moves up and down between two seat rings to control the flow. They provide a tight seal and are suitable for applications with high-pressure and high-temperature conditions.

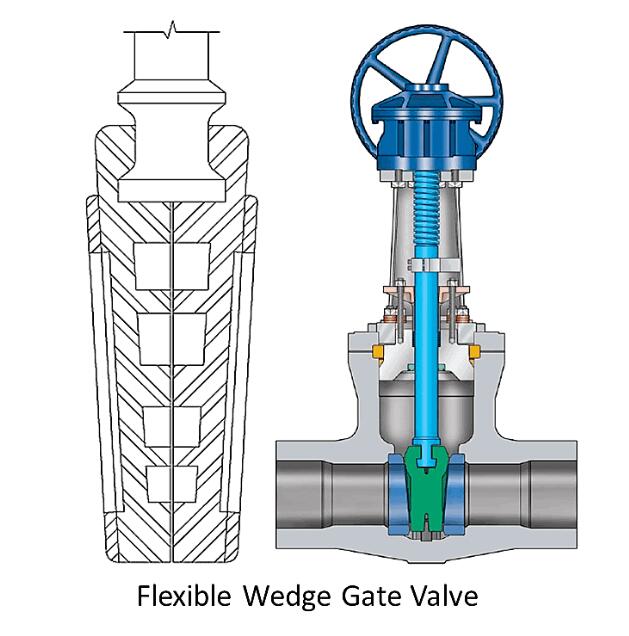

Flexible Wedge Gate Valve:

Flexible wedge gate valves feature a wedge-shaped gate with a split in the middle, allowing the gate to flex slightly to improve sealing performance on imperfectly aligned seats. This type is suitable for applications with temperature variations or thermal cycling.

Knife Gate Valve:

Knife gate valves have a sharp-edged gate that slices through the flow to shut off the valve. They are commonly used in applications with viscous fluids, slurries, or solids, such as wastewater treatment, pulp and paper, and mining.

Pressure Seal Gate Valve:

Pressure seal gate valves are designed for high-pressure applications. They feature a bonnet with a pressure seal gasket that provides additional sealing force as the pressure increases.

Chapter 4 - Stainless Steel Gate Valve application

Stainless steel gate valves find applications across various industries due to their corrosion resistance, durability, and ability to handle high temperatures and pressures. Here are some common applications:

Water and Wastewater Treatment:

Stainless steel gate valves are widely used in water treatment plants and wastewater treatment facilities to control the flow of water, chemicals, and sludge. They are suitable for both clean water applications and those involving corrosive or abrasive fluids.

Oil and Gas Industry:

Gate valves play a critical role in the oil and gas industry for controlling the flow of crude oil, natural gas, and various hydrocarbons. Stainless steel gate valves are preferred for their resistance to corrosion in harsh environments such as offshore drilling rigs and onshore processing facilities.

Petrochemical Plants:

Petrochemical plants utilize stainless steel gate valves in processes involving the refining, processing, and transportation of petroleum-based products. These valves are essential for isolating sections of pipelines, controlling flow rates, and maintaining safety.

Chemical Processing:

Stainless steel gate valves are commonly used in chemical processing plants to regulate the flow of corrosive chemicals and solvents. They provide reliable sealing and resistance to chemical attack, making them suitable for handling a wide range of corrosive fluids.

Pharmaceutical Industry:

Stainless steel ball valves are used in pharmaceutical manufacturing for controlling the flow of liquids and gases in various production processes.

Power Generation:

Gate valves are integral components in power plants for controlling steam, water, and other fluids in boiler feedwater systems, steam turbine bypass lines, and cooling water circuits. Stainless steel gate valves are preferred for their resistance to high temperatures and pressures.

HVAC System:

In heating, ventilation, and air conditioning (HVAC) systems, stainless steel gate valves are used for controlling the flow of water and other fluids in piping networks. They help regulate the temperature, pressure, and flow rate of heating and cooling fluids in commercial and residential buildings.

Marine and Offshore Industry:

Stainless steel gate valves are utilized in marine applications aboard ships, vessels, and offshore platforms. They are suitable for seawater systems, ballast systems, bilge systems, and other critical marine applications due to their resistance to corrosion from saltwater environments.

Food and Beverage Industry:

Gate valves made of stainless steel are used in food processing and beverage production facilities to control the flow of ingredients, water, and cleaning solutions. They meet hygiene standards and withstand the demanding conditions of food processing environments.

Pharmaceutical Industry:

In pharmaceutical manufacturing facilities, stainless steel gate valves are employed for controlling the flow of pharmaceutical ingredients, solvents, and process fluids. They meet stringent cleanliness and sterilization requirements to ensure product purity and safety.

Mining and Minerals Processing:

Gate valves are utilized in mining operations for controlling the flow of slurries, process water, and chemicals in ore processing plants and mining pipelines. Stainless steel gate valves are chosen for their resistance to abrasion and corrosion in harsh mining environments.