Stainless Steel Ball Valve

Introduction

This article contains all the information you need to know about Stainless Steel Ball Valves.

Secification

Actuator

Types

Application

Chapter 1 - Specification

Stainless steel ball valves are usually made from corrosion-resistant stainless steel alloys such as 304, 316, 316L, or 904L. The material selection depends on factors such as the fluid being handled, temperature, pressure, and environmental conditions.

Seat Material

The material used for the valve seat affects its sealing performance and compatibility with different fluids. Common seat materials include PTFE (Teflon), reinforced PTFE, RPTFE (reinforced polytetrafluoroethylene), and metal.

Size

Kamroo Ball valves are available in a range of sizes, typically from 1/4 inch to 12 inches or larger. The size of the valve determines its flow capacity and compatibility with existing piping systems.

Pressure Rating

The pressure rating specifies the maximum pressure the valve can safely withstand while in operation. Stainless steel ball valves are rated for specific pressure ranges, such as 150 psi, 300 psi, 600 psi, 900 psi, etc.

Temperature Range

The temperature range indicates the minimum and maximum temperatures at which the valve can operate without compromising its performance or integrity. Stainless steel ball valves are often suitable for a wide temperature range, but it's essential to verify compatibility for extreme temperatures.

End Connections

Stainless steel ball valves can be connected to piping systems using various types of end connections, each offering specific advantages depending on the application and installation requirements. Here are some common types of connections for stainless steel ball valves:

Threaded Connections (NPT/BSP)

Flanged Connections

Socket Weld Connections

Butt Weld Connections

Tri-Clamp Connections

Compression Tube Connection

Wafer Connections

Grooved Connections

Chapter 2 - Stainless Steel Ball Valve Actuator

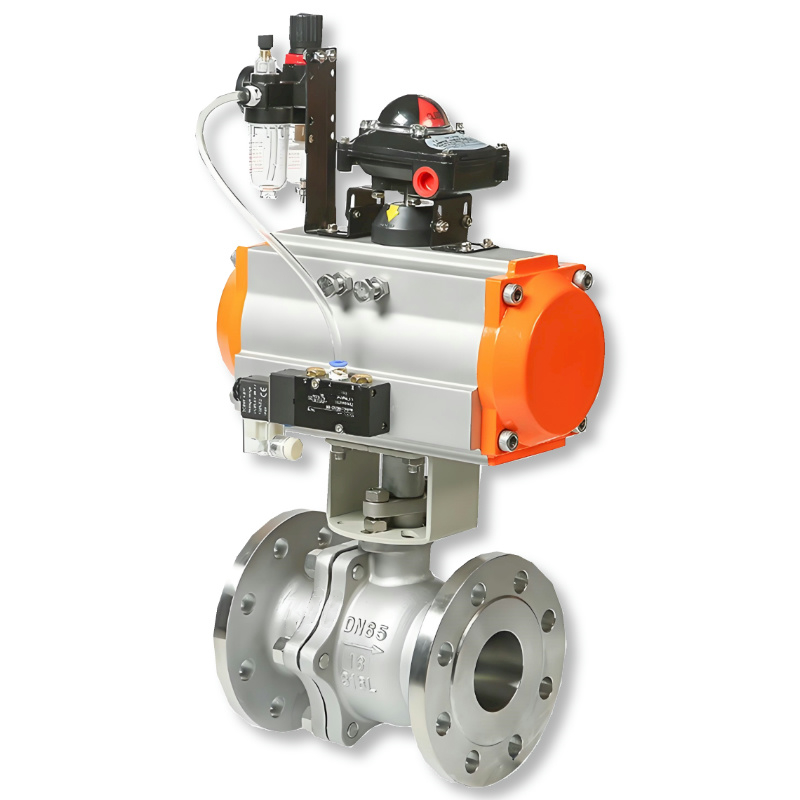

Kamroo Valve stainless steel ball valves can be equipped with actuators to enable remote or automated operation, enhancing their functionality and versatility in industrial applications. Actuators provide the means to open, close, or modulate the valve position without manual intervention. Here are some common types of actuators used with stainless steel ball valves:

Pneumatic Actuators:

Pneumatic actuators use compressed air to generate mechanical motion, which is then transferred to the valve to operate it. They are known for their fast response times, reliability, and suitability for hazardous environments. Pneumatic actuators are often used in industries such as manufacturing, petrochemical, and water treatment.

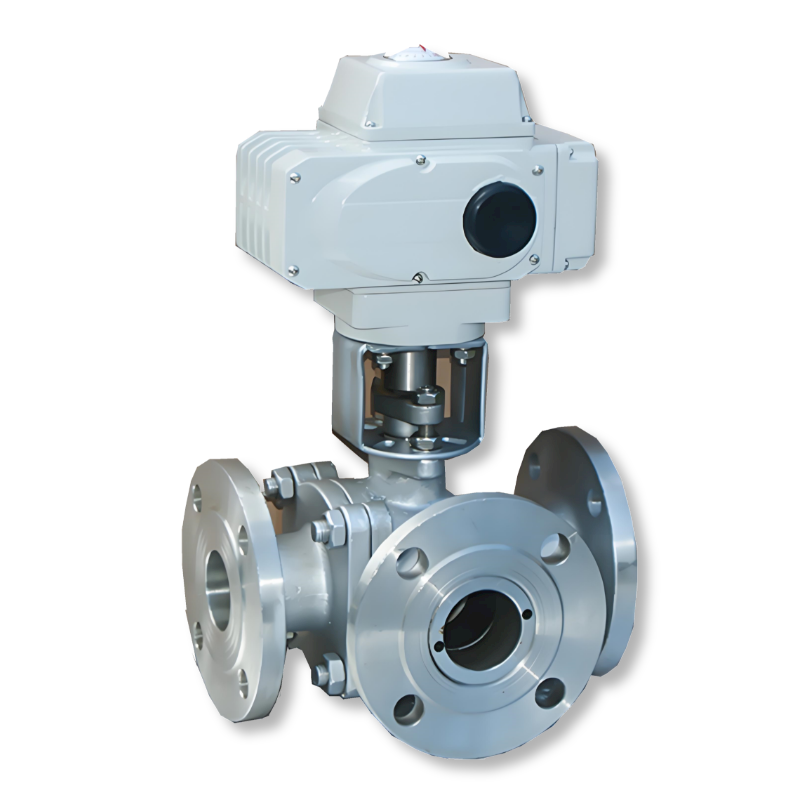

Electric Actuators:

Electric actuators use electric motors to drive the valve's movement. They offer precise control over valve position and can be easily integrated into control systems for automation and remote operation. Electric actuators are commonly used in applications requiring accurate positioning, such as process control and HVAC systems.

Hydraulic Actuators:

Hydraulic actuators use hydraulic fluid to generate mechanical force, which is then used to operate the valve. They offer high force output and are suitable for applications requiring heavy-duty operation or high-pressure environments. Hydraulic actuators are commonly used in industries such as oil and gas, power generation, and aerospace.

Manual Override:

Some actuated stainless steel ball valves feature manual override capabilities, allowing manual operation of the valve in case of power failure or emergency situations. This provides an added layer of safety and redundancy in critical applications.

Spring-Return Actuators:

Spring-return actuators use a spring mechanism to return the valve to a pre-determined position (usually closed or open) in case of power loss. They are commonly used in fail-safe applications where maintaining a specific valve position is crucial for safety or process integrity.

Chapter 3 - Stainless Steel Ball Valve types

Kamroo Valve Stainless steel ball valves come in various types, each tailored to specific applications and flow control needs. Here are some common types:

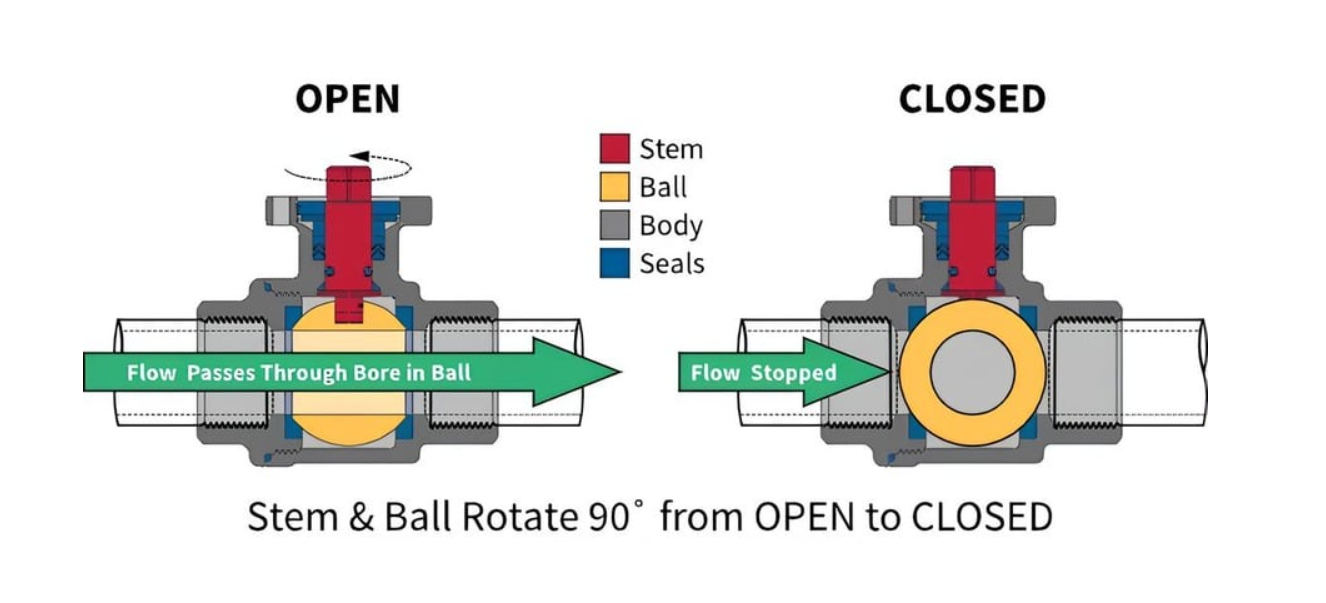

Two-Way Ball Valve:

This is the most basic type, featuring a single inlet and outlet port. It controls the flow by either allowing or blocking it entirely.

Three-Way Ball Valve:

Three-way ball valves have three ports and are used for diverting or mixing flow between two different paths. They can be configured in different ways, such as L-port and T-port designs, allowing for various flow patterns.

Floating Ball Valve:

In this type, the ball is not fixed to the stem but floats between the seat rings. When the pressure of the fluid increases, it pushes the ball against the seat, creating a seal. Floating ball valves are suitable for moderate to high-pressure applications.

Trunnion Ball Valve:

Trunnion ball valves have additional mechanical anchoring of the ball at the top and bottom to withstand higher pressures and larger sizes. They are commonly used in pipelines with high-pressure or high-volume flow requirements.

Chapter 4 - Stainless Steel Ball Valve application

Stainless steel ball valves are commonly used in a wide range of industrial applications due to their durability, corrosion resistance, and ability to handle high-pressure and high-temperature environments. Some common applications include:

Oil and Gas Industry:

Stainless steel ball valves are used extensively in the oil and gas industry for controlling the flow of various fluids such as crude oil, natural gas, and refined products.

Chemical Processing:

They are used in chemical processing plants to regulate the flow of corrosive chemicals and solvents.

Water and Wastewater Treatment:

Stainless steel ball valves are suitable for water treatment facilities, where they are used to control the flow of water, chemicals, and wastewater.

Food and Beverage Industry:

They are utilized in food and beverage processing plants for controlling the flow of liquids such as water, juices, and dairy products. Stainless steel is preferred in these applications due to its hygienic properties.

Pharmaceutical Industry:

Stainless steel ball valves are used in pharmaceutical manufacturing for controlling the flow of liquids and gases in various production processes.

Petrochemical Industry:

They find applications in petrochemical plants for controlling the flow of petrochemical products such as gasoline, diesel, and other refined fuels.

HVAC (Heating, Ventilation, and Air Conditioning):

Stainless steel ball valves are used in HVAC systems for regulating the flow of water or refrigerants.

Marine and Offshore Industry:

Due to their resistance to corrosion from seawater, stainless steel ball valves are commonly used in marine and offshore applications, such as shipbuilding, offshore oil rigs, and ports.

Power Generation:

They are used in power plants for controlling the flow of steam, water, and other fluids in various processes, including boiler systems and cooling circuits.

Industrial Manufacturing:

Stainless steel ball valves find applications in various industrial manufacturing processes where precise control of fluid flow is required.