Wafer Butterfly Valve

Introduction

This article contains all the information you need to know about Wafer Butterfly Valve

Read further and learn more about:

Specification

Actuators

Types

Application

Chapter 1 - Wafer Butterfly Valve Specification

Here's a typical specification for a wafer butterfly valve:

Body Material

Typically constructed from cast iron, ductile iron, carbon steel, stainless steel, or other suitable materials for the intended application. Common materials include ASTM A216 WCB, ASTM A351 CF8M, ASTM A352 LCB, ASTM A217 WC6, etc.

Disk Material:

The disc may be made of the same material as the body or may have a different material for corrosion resistance or other specific requirements. Common disc materials include stainless steel, duplex stainless steel, nickel alloy, and others.

Seat Material:

The seat material is typically made of an elastomer such as EPDM (ethylene propylene diene monomer), NBR (nitrile butadiene rubber), Viton, or PTFE (polytetrafluoroethylene). The seat material is selected based on compatibility with the fluid, temperature range, and pressure rating.

Valve Size

Available in various sizes typically ranging from 2" to 48" (larger sizes may be available upon request).

Pressure Rating

ANSI Class 150, 300, 600, or higher, indicating the maximum pressure the valve can withstand. The selection of pressure rating depends on the specific application requirements.

Temperature Range

The valve should be suitable for operating temperatures ranging from -29°C to 200°C (-20°F to 392°F) or higher, depending on the seat and elastomer materials selected.

Connection Type

The wafer butterfly valve features wafer-style connections designed to fit between two flanges. They are typically installed using bolts and nuts, sandwiching the valve between the flanges. The valve conforms to relevant standards such as ASME B16.5, ASME B16.47 Series A or Series B, API 609, EN 1092, or others.

Design Standards:

The valve design should comply with industry standards such as API 609, MSS SP-68, or AWWA C504 for construction, design, and testing requirements specific to butterfly valves.

Compliance:

The valve should comply with relevant industry standards and regulations such as ASME, ANSI, API, ASTM, MSS-SP, and others, depending on the application and location.

Chapter 2 - Wafer Butterfly Valve Actuator

Wafer butterfly valves can be operated manually or with the assistance of actuators for remote control, automation, and precise regulation of fluid flow. Here are some common types of actuators used with wafer butterfly valves:

Manual Actuators:

Manual actuators include hand-operated levers, gear operators, or handwheels. These actuators allow operators to manually open, close, or adjust the position of the valve. Manual actuators are simple, cost-effective, and suitable for applications where frequent adjustments are not required or where power sources are limited.

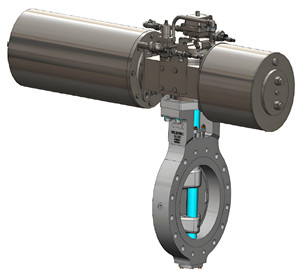

Pneumatic Actuators:

Pneumatic actuators use compressed air to operate the valve. They convert pneumatic energy into mechanical motion to open, close, or modulate the valve position. Pneumatic actuators are known for their fast response times, precise control, and suitability for hazardous or explosive environments. They are commonly used in industrial processes where quick valve operation and automation are required.

Electric Actuators:

Electric actuators use an electric motor to operate the valve. They offer precise control over valve positioning and can be easily integrated into control systems. Electric actuators are suitable for applications where remote operation, automation, and precise positioning are required. They are commonly used in industries such as water treatment, HVAC, and process automation.

Hydraulic Actuators:

Hydraulic actuators use hydraulic fluid to operate the valve. They offer high force output and precise control over valve movement, making them suitable for high-pressure and high-torque applications. Hydraulic actuators are commonly used in industries such as marine, offshore, and heavy machinery, where reliable and powerful valve actuation is required.

Spring-Return Actuators:

Spring-return actuators use a spring mechanism to return the valve to a predefined position when power or pressure is removed. They are commonly used in safety-critical applications where fail-safe operation is required, such as emergency shutdown systems. Spring-return actuators provide reliable valve positioning in the event of power failure or emergency situations.

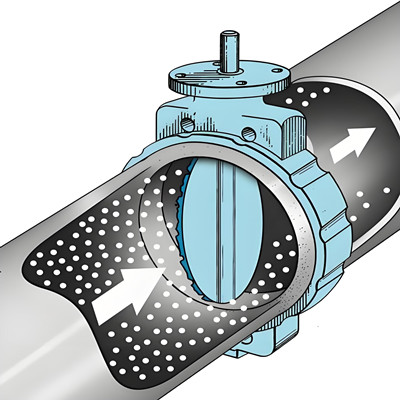

Chapter 3 - Wafer Butterfly Valve Types

Wafer butterfly valves come in various types, each designed to meet specific application requirements and conditions. Here are some common types of wafer butterfly valves:

Centerline Butterfly Valve:

Centerline butterfly valves have their disc centered within the pipe bore. These valves are symmetrical, with the shaft passing through the center of the disc and seat. Centerline butterfly valves provide reliable sealing and are suitable for general-purpose applications with moderate pressure and temperature requirements.

Double Offset Butterfly Valve:

Double offset butterfly valves feature a disc offset from both the centerline of the valve body and the shaft. This design reduces friction between the disc and seat, resulting in improved sealing performance and longer service life. Double offset butterfly valves are suitable for high-pressure, high-temperature, and critical applications such as oil and gas, refining, and power generation.

Triple Offset Butterfly Valve:

Triple offset butterfly valves have three offsets: one from the centerline of the valve body, one from the centerline of the disc, and one from the centerline of the seat. This advanced design minimizes friction and achieves bubble-tight shut-off even in high-temperature and high-pressure applications. Triple offset butterfly valves are widely used in industries such as oil and gas, petrochemicals, and chemical processing.

Lug Type Butterfly Valve:

Lug type butterfly valves have threaded inserts or lugs on the valve body, allowing them to be bolted between two flanges without the need for additional gaskets. These valves are easy to install and remove from the pipeline, making them suitable for applications where frequent maintenance or replacement is required.

Wafer Type Butterfly Valve:

Wafer type butterfly valves are designed to fit between two flanges using bolts and nuts, sandwiching the valve between the flanges. They are compact, lightweight, and cost-effective, making them suitable for a wide range of applications in industries such as water treatment, HVAC, and general industrial use.

High-Performance Butterfly Valve:

High-performance butterfly valves are designed to handle higher pressures, temperatures, and flow rates compared to standard butterfly valves. They feature robust construction, metal-to-metal sealing, and advanced design features for demanding applications in industries such as power generation, oil and gas, and refining.

Resilient Seated Butterfly Valve:

Resilient seated butterfly valves have a soft seat made of elastomeric materials such as EPDM, NBR, or Viton. These valves provide reliable sealing and are suitable for applications where tight shut-off and low torque operation are required.

Metal Seated Butterfly Valve:

Metal seated butterfly valves feature a metal seat and disc, providing tight shut-off and resistance to high temperatures and abrasive media. These valves are suitable for applications where soft-seated valves may be damaged or degraded due to abrasive or high-temperature conditions.

Chapter 4 - Wafer Butterfly Valve Application

Wafer butterfly valves are versatile components widely used across various industries for controlling the flow of fluids. Their compact design, lightweight construction, and ease of installation make them suitable for a wide range of applications. Here are some common applications of wafer butterfly valves:

Oil and Gas Industry:

Hard metal seal butterfly valves are used in upstream, midstream, and downstream operations within the oil and gas industry. They are installed in pipelines, wellheads, manifold systems, and processing facilities to control the flow of crude oil, natural gas, and refined products. These valves are suitable for high-pressure and high-temperature applications, as well as corrosive environments found in offshore platforms, refineries, and petrochemical plants.

Chemical Processing:

Hard metal seal butterfly valves find application in chemical processing plants for handling corrosive chemicals, acids, and solvents. They are used in reactors, distillation columns, storage tanks, and mixing vessels to control the flow of process fluids and maintain system integrity. These valves offer tight shut-off and resistance to chemical corrosion, making them suitable for aggressive chemical environments.

Power Generation:

Hard metal seal butterfly valves are utilized in power plants for controlling the flow of steam, water, and other fluids in boiler feedwater systems, steam turbines, condensers, and cooling towers. They are designed to withstand high temperatures, pressures, and steam conditions commonly encountered in power generation facilities. These valves provide reliable shut-off and flow control in critical steam and water applications.

Mining and Minerals:

Hard metal seal butterfly valves are used in mining and mineral processing operations for controlling the flow of slurries, mine tailings, and process fluids. They are installed in pipelines, pumps, and processing equipment to handle abrasive and corrosive materials found in mining operations. These valves offer tight shut-off and resistance to abrasion and erosion, making them suitable for harsh mining environments.

Water and Wastewater Treatment:

Hard metal seal butterfly valves find application in water and wastewater treatment plants for controlling the flow of water, chemicals, and sludge. They are used in pipelines, treatment tanks, and filtration systems to regulate fluid flow and maintain process efficiency. These valves offer resistance to corrosion and chemical attack, ensuring reliable performance in water treatment applications.

Marine and Offshore:

Hard metal seal butterfly valves are employed in marine and offshore applications for controlling the flow of seawater, ballast water, and hydraulic fluids. They are installed in piping systems aboard ships, offshore platforms, and marine vessels to regulate fluid flow and maintain system reliability in challenging marine environments. These valves offer resistance to corrosion, erosion, and fouling, making them suitable for marine applications.