Ultra-low Temperature Globe Valve

Introduction

This article contains all the information you need to know about Ultra-low Temperature Globe Valve

Specification

Types

Application

Chapter 1 - Specification

For ultra-low temperature applications, such as those involving cryogenic fluids like liquid nitrogen, liquid oxygen, or liquefied natural gas (LNG), specialized globe valves are required to ensure reliable performance and safety. Here's a typical specification for an ultra-low temperature globe valve:

Body Material

The body material is usually selected to withstand ultra-low temperatures. Common materials include:

Stainless Steel: ASTM A351 CF8M (316 stainless steel) or ASTM A351 CF8 (304 stainless steel) for excellent corrosion resistance and cryogenic properties.

Low-Temperature Carbon Steel: ASTM A352 LCC (low-carbon steel) or ASTM A352 LC3 (3.5% nickel steel) for enhanced toughness and ductility at low temperatures.

Trim Material:

The trim materials are typically selected for cryogenic service and may include:

Stainless Steel:ASTM A276 Type 316 or ASTM A276 Type 304 for cryogenic applications.

Special Alloys:Inconel, Monel, or Hastelloy for enhanced corrosion resistance and low-temperature performance.

Seat Material:

Seats are usually made of materials such as PCTFE (polychlorotrifluoroethylene) or PTFE (polytetrafluoroethylene) for excellent sealing performance at ultra-low temperatures.

Valve Size

Typically available in sizes ranging from 1/2" to 24" (larger sizes may be available on request).

Bonnet Type:

Bolted bonnet or welded bonnet design, depending on the pressure rating and temperature requirements of the application. Welded bonnets are preferred for cryogenic applications to minimize potential leak paths.

Pressure Rating

ANSI Class 150, 300, 600, or higher, depending on the application requirements and operating conditions.

Temperature Range

Suitable for operating temperatures ranging from -196°C to -40°C (-320°F to -40°F) or lower, depending on the fluid being handled and the specific application requirements.

End Connections

Flanged ends, conforming to ASME B16.5 standards, with raised face (RF), flat face (FF), or ring joint face (RTJ) options available. Special attention should be given to gasket materials suitable for cryogenic service.

Design Standards:

The valve design should comply with international standards such as API 600, API 602, ASME B16.34, or equivalent for construction, design, and testing requirements specific to cryogenic service.

Compliance:

The valve should comply with relevant industry standards and regulations such as ASME, ANSI, API, ASTM, MSS-SP, and others, specific to cryogenic service.

Chapter 2 - Ultra-low Temperature Globe Valve Types

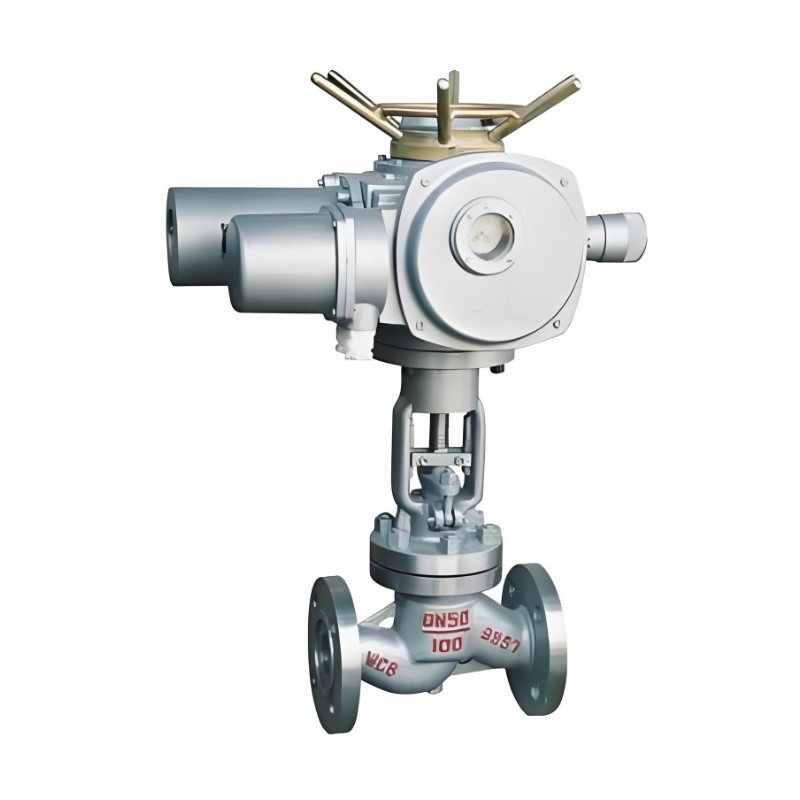

For ultra-low temperature applications, especially in industries like cryogenics, where temperatures can drop significantly, the choice of actuator for a globe valve becomes crucial. Here are some considerations and potential options for actuators suitable for ultra-low temperature globe valves:

Pneumatic Actuators with Low-Temperature Seals:

Pneumatic actuators are commonly used in industrial applications due to their reliability and efficiency. For ultra-low temperature environments, special pneumatic actuators with low-temperature seals can be used. These seals are designed to withstand extremely cold temperatures without losing their sealing properties.

Electric Actuators with Cryogenic Ratings:

Electric actuators offer precise control and can be suitable for ultra-low temperature applications if they are rated for cryogenic service. These actuators are specially designed to operate in extremely cold environments and may incorporate features such as insulated housing and low-temperature lubricants.

Manual Actuators with Insulated Handles:

In some cases, manual actuators may be used for ultra-low temperature globe valves. These actuators typically feature insulated handles or grips to protect the operator's hands from the cold. However, manual operation may not be suitable for all applications, especially if precise control or remote operation is required.

Chapter 3 - Ultra-low Temperature Globe Valve Types

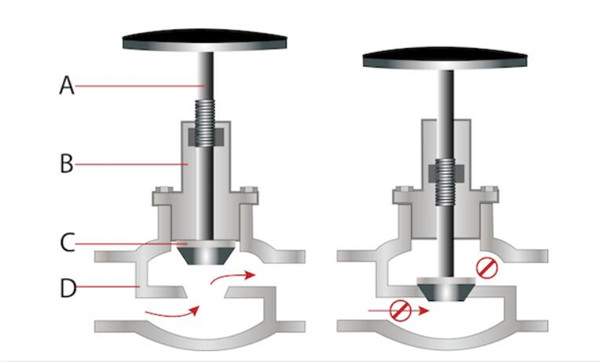

For ultra-low temperature applications, such as those involving cryogenic fluids like liquid nitrogen, liquid oxygen, or liquefied natural gas (LNG), specialized globe valve designs are necessary to ensure reliable performance and safety. While there aren't distinct "types" of ultra-low temperature globe valves in the same way as there are for other valve configurations, such as gate valves or ball valves, there are variations and features that differentiate them based on specific requirements and applications. Here are some common variations you might encounter:

Extended Bonnet Globe Valve:

These valves feature an extended bonnet that provides additional insulation and protection for the valve stem and internal components. The extended bonnet helps to maintain the integrity of the valve at ultra-low temperatures and prevents freezing of the packing and stem.

Cryogenic Globe Valve with Extended Stem:

In this design, the valve stem is extended beyond the bonnet to keep the valve packing and stem out of the cold zone, reducing the risk of freezing and ensuring smooth operation in cryogenic environments.

Low-Temperature Globe Valve:

These valves are specifically designed and manufactured to withstand ultra-low temperatures and maintain their integrity and performance in cryogenic applications. They are typically constructed using materials with excellent cryogenic properties, such as stainless steel or low-temperature carbon steel, and feature specialized sealing and lubrication systems to prevent freezing and ensure smooth operation.

Bellows Seal Globe Valve:

Bellows seal globe valves feature a bellows-type seal between the valve stem and the bonnet, providing a leak-tight seal even in ultra-low temperature applications. The bellows seal prevents fluid leakage and minimizes the risk of stem freezing, ensuring reliable performance in cryogenic environments.

High-Performance Cryogenic Globe Valve:

These valves are designed for critical applications where tight shut-off and precise flow control are required in cryogenic environments. They feature advanced sealing technologies, such as metal-to-metal or graphite packing, to ensure leak-tight performance even at extreme temperatures.

Forged Steel Cryogenic Globe Valve:

not strictly a different "type," some globe valves are specifically forged to withstand ultra-low temperatures. Forged steel cryogenic globe valves offer high strength and reliability and are suitable for high-pressure cryogenic applications.

Chapter 4 - Ultra-low Temperature Globe Valve Application

Ultra-low temperature globe valves find application in various industries and processes where the handling of cryogenic fluids is involved. Here are some common applications:

Liquefied Natural Gas (LNG) Industry:

Ultra-low temperature globe valves are essential components in LNG processing plants, storage facilities, and transportation systems. They are used for controlling the flow of liquefied natural gas during liquefaction, storage, loading, unloading, and regasification processes.

Industrial Gas Production and Distribution:

Globe valves are utilized in the production, storage, and distribution of industrial gases such as liquid nitrogen, liquid oxygen, and liquid hydrogen. They are used for controlling the flow of cryogenic fluids in gas processing plants, air separation units, and cryogenic storage tanks.

Cryogenic Storage and Transportation:

Globe valves are employed in cryogenic storage tanks, vessels, and pipelines for storing and transporting cryogenic fluids at ultra-low temperatures. They help regulate the flow of fluids during loading, unloading, and transfer operations.

Research Laboratories and Facilities:

Ultra-low temperature globe valves are used in research laboratories, scientific facilities, and experimental setups where cryogenic fluids are handled for various research and testing purposes. They are employed in cryostats, cryogenic chambers, and cryogenic cooling systems.

Medical and Healthcare:

Globe valves find application in medical and healthcare facilities for controlling the flow of cryogenic fluids used in medical imaging, cryosurgery, cryopreservation, and other medical procedures. They are used in MRI machines, cryogenic storage units, and cryosurgical instruments.

Aerospace and Aviation:

Globe valves are utilized in aerospace and aviation applications for controlling the flow of cryogenic fluids used as propellants, coolants, and pressurants in rocket engines, spacecraft, and satellite propulsion systems.

Food and Beverage Industry:

Globe valves find application in the food and beverage industry for controlling the flow of cryogenic fluids used in food processing, freezing, and preservation. They are used in cryogenic food freezing tunnels, cryogenic grinding systems, and cryogenic storage tanks for food products.

Energy and Environmental Applications:

Globe valves are utilized in energy and environmental applications for controlling the flow of cryogenic fluids used in energy storage, liquefaction of gases, and carbon capture and storage (CCS) systems.

Oil and Gas Exploration:

Ultra-low temperature globe valves find application in oil and gas exploration and production operations where cryogenic fluids are used for well stimulation, drilling, and completion activities. They are employed in cryogenic fracturing, well testing, and LNG-powered drilling rigs.