Metal Seal High Temperature Ball Valve

Introduction

This article contains all the information you need to know about Metal Seal High Temperature Ball Valve

Specification

Actuator

Types

Application

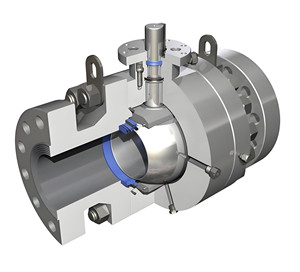

Chapter 1 - Metal Seal High Temperature Ball Valve

Metal seal high-temperature ball valves are designed to withstand extreme temperatures and harsh operating conditions while providing reliable flow control. Here are some typical specifications you might find for such valves:

Material:

Body Material:

The body of the valve is usually made from high-temperature-resistant alloys such as stainless steel (e.g., ASTM A351 CF8M, CF8C), alloy steel (e.g., ASTM A217 WC6, WC9), or other heat-resistant alloys such as Inconel or Hastelloy.

Ball Material:

The ball is typically made from the same high-temperature-resistant material as the body, ensuring compatibility and durability under extreme conditions.

Seat Material:

Metal-to-metal seals are commonly used in high-temperature ball valves to ensure tight shut-off and reliability. Materials such as stellite, tungsten carbide, or other hard alloys may be used for the sealing surfaces to withstand high temperatures and abrasive media.

Pressure Rating

These valves are typically rated for high-pressure applications, often ranging from ANSI Class 150 to Class 2500 or higher, depending on the valve size and design.

Temperature Range

Metal seal high-temperature ball valves are designed to operate in temperatures ranging from several hundred to over a thousand degrees Celsius (depending on the specific design and materials used). The temperature rating should be clearly specified by the manufacturer.

End Connections

These valves may come with various end connection options, including flanged, threaded, or welded ends, depending on the application and installation requirements.

Chapter 2 - Metal Seal High Temperature Ball Valve Actuator

For metal seal high-temperature ball valves, selecting the appropriate actuator is crucial to ensure reliable operation and control in harsh environments. Here are some considerations and options for actuators suitable for these valves:

Pneumatic Actuators with High-Temperature Seals:

Pneumatic actuators are commonly used in industrial applications due to their reliability and quick response. For high-temperature ball valves, pneumatic actuators with high-temperature seals are essential to withstand the elevated temperatures. These seals are designed to maintain their integrity and sealing performance even in extreme heat conditions.

Electric Actuators with High-Temperature Ratings:

Electric actuators offer precise control and are suitable for high-temperature applications when rated for such conditions. These actuators should feature components such as high-temperature insulation, heat-resistant materials, and suitable lubricants to ensure reliable performance in elevated temperatures.

Hydraulic Actuators with High-Temperature Fluids:

Hydraulic actuators provide high force output and can be suitable for high-temperature ball valves when equipped with high-temperature hydraulic fluids. These fluids are formulated to maintain their viscosity and performance in extreme heat, ensuring smooth operation of the actuator.

Manual Override:

In some cases, manual override capabilities may be necessary for high-temperature ball valves to provide fail-safe operation in the event of power or system failures. Manual handwheels or levers can be integrated into the actuator design to allow for manual operation when needed.

Chapter 3 - Metal Seal High Temperature Ball Valve Types

Ultra-low temperature ball valves are designed to withstand extremely cold environments, typically below -50°C (-58°F), and are commonly used in industries such as cryogenics, aerospace, and research laboratories. Several types of ultra-low temperature ball valves are available to meet various application requirements. Here are some common types:

Top-Entry Ball Valves:

Top-entry ball valves feature a top-entry design where the valve body can be disassembled from the top, allowing for easy maintenance and repair without removing the valve from the pipeline. This design is beneficial in cryogenic applications where frequent maintenance may be required.

Trunnion-Mounted Ball Valves:

Trunnion-mounted ball valves are designed with a fixed ball supported by trunnion bearings, providing increased stability and reliability, especially in high-pressure and high-temperature applications. They can also be adapted for ultra-low temperature service with appropriate materials and design considerations.

Full-Bore (Full-Port) Ball Valves:

Full-bore ball valves have a larger ball opening, offering minimal flow restriction and improved flow characteristics compared to reduced-bore valves. They are suitable for applications where maximum flow capacity is required, including cryogenic applications with high flow rates.

Floating Ball Valves:

Floating ball valves feature a ball that floats between two seats, allowing the ball to move freely within the valve body. These valves are suitable for moderate-pressure applications and can be adapted for ultra-low temperature service with appropriate materials and design considerations.

Three-Way and Multiport Ball Valves:

Three-way and multiport ball valves have multiple ports and flow paths, allowing for diversion or mixing of flow within a single valve body. These valves are used in applications where multiple process streams need to be controlled or redirected, including cryogenic processes.

Fully Welded Ball Valves:

Fully welded ball valves have welded construction, eliminating potential leak paths and enhancing structural integrity. They are commonly used in pipelines carrying cryogenic fluids to prevent fugitive emissions and ensure safe operation at ultra-low temperatures.

These are just a few examples of the types of ultra-low temperature ball valves available in the market. Each type may have specific features and advantages tailored to different applications and operating conditions. When selecting a valve for ultra-low temperature service, it's essential to consider factors such as temperature range, pressure rating, material compatibility, flow characteristics, and maintenance requirements to ensure optimal performance and reliability in cryogenic environments.

Chapter 4 - Metal Seal High Temperature Ball Valve application

Ultra-low temperature ball valves find application in various industries and processes where extreme cold conditions are encountered. Here are some common applications:

Cryogenic Storage and Transportation:

Ultra-low temperature ball valves are used in the storage and transportation of cryogenic fluids such as liquid nitrogen, liquid oxygen, liquid hydrogen, and liquefied natural gas (LNG). They help regulate the flow of cryogenic fluids in storage tanks, tankers, pipelines, and processing facilities.

LNG Terminals and Facilities:

LNG terminals and facilities require valves capable of withstanding the extremely low temperatures associated with liquefied natural gas. Ultra-low temperature ball valves are employed in LNG liquefaction plants, regasification terminals, storage tanks, and loading/unloading terminals to control the flow of LNG throughout the process.

Industrial Gases:

These valves are used in the production, storage, and distribution of industrial gases such as nitrogen, argon, helium, and oxygen. Ultra-low temperature ball valves help manage the flow of cryogenic gases in air separation plants, gas storage facilities, and specialty gas applications.

Aerospace and Defense:

Ultra-low temperature ball valves are utilized in aerospace and defense applications where cryogenic fluids are used, such as rocket propulsion systems, satellite propulsion, and cryogenic fueling stations. These valves help regulate the flow of liquid propellants and ensure reliable operation in space exploration missions.

Research Laboratories and Scientific Facilities:

Laboratories and research facilities involved in cryogenics, superconductivity, and low-temperature physics rely on ultra-low temperature ball valves for handling cryogenic fluids and maintaining precise temperature control. These valves are used in experiments, test rigs, and equipment requiring ultra-low temperature conditions.

Medical and Healthcare:

Ultra-low temperature ball valves play a role in medical and healthcare applications, particularly in cryosurgery, cryopreservation, and biomedical research. They are used in cryogenic storage systems for storing biological samples, tissues, and cells at ultra-low temperatures.

Food and Beverage Industry:

In the food and beverage industry, ultra-low temperature ball valves may be used in applications such as cryogenic freezing, chilling, and storage of food products. They help maintain the quality and freshness of perishable goods by ensuring precise temperature control during processing and storage.

Energy and Power Generation:

Ultra-low temperature ball valves are employed in energy and power generation facilities for handling cryogenic fluids in applications such as liquefied natural gas (LNG) regasification, cryogenic cooling systems, and superconducting power transmission.

These are just a few examples of the diverse applications of ultra-low temperature ball valves. In general, they are essential components in industries and processes where extreme cold conditions are encountered, providing reliable flow control and safety in cryogenic environments.